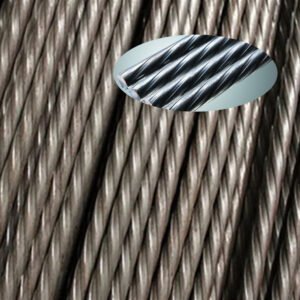

FOR Korea VIETNAM Cambodia 30MnSi 12.6mm Twisted Prestressed Concrete Steel Bar Iron Rod For Concrete

PC Steel Bar is one of our major products involves in construction industry, it is mainly used on PHC( High strength prestressed concrete pipe pile), Concrete Spun Pile, telegraph Pole, telecome Pole etc.. Besides domestic market, we also export to Korea,Vietnam, Malaysia,Indonesia,Cambodia etc foreign countries. We are the offcially approved manufacturer to produce PC bar according to Japanese Industrial Standards.

PC Bar is an important one of our main products, which is mainly used in Large-scale bridges, Freeways, Highways, Mines, High-rise building, Cement products and other construction field with high strength, low usage of metallic material, convenience usage .

PC steel bar information:

1, Technical parameters of PC BAR

Nominal diameter : 7.1mm 9.0mm 10.7mm 12.6mm Production standard : MS1138 :PART 3

Tensile strength : ≥ 1420Mpa Yield strength : ≥ 1280Mpa

Elongation : ≥ 7.0% Relaxation :≤ 2.0%

Straightness :≤ 2mm/m Material: 30MnSi

Weight per coil : 1ton-2ton

2, Chemical composition (%) of PC BAR –Material 30MnSi

C : 0.28-0.33 Si: 0.60-0.90 Mn: 0.90-1.30 P(Max): 0.03 S(Max) : 0.035 Cu(Max) : 0.3

3, Other info about PC bar:

Production standard : JIS G 3137 SBPDL 1275/1420 KSD3505 MS1138:PART 3 SNI 7701:2016

Packing : Tied with at least 8 steel strips per coil, wrapped with PP woven or stretch film

Coil weight : Approx. 0.9MT and 1.3MT Diameter of Coil Inside Dia.:1.99m Outside Dia.:2.3m Height:18cm

Application: Pre-stressed concrete pile /Spun piles /Poles

PC bar for mine anchor cable (mine supporting big diameter PC bar)

This product is heat-treated spiral rib bar with resin anchoring structure for mine anchor cable. Its specifications are φ16.0mm, φ18.0mm, φ20mm, and the tensile strength grade are 1080Mpa, 1270Mpa, and 1420Mpa. The product has the characteristics of high strength, high toughness, low relaxation, total elongation under maximum force Agt≥3.5% and impact absorption energy Akv/J≥32. Its shape is spiral rib. It is a new type of support material that combines the advantages of ordinary resin anchor rod and high-strength PC strand materials. During application, it adopts tensioning method to apply preload and only the tail of the bar is stretched to avoid the torsion of traditional anchor rods caused by applying preload through pre-tightening torque and breakage in shear. The tensioning method can also greatly increase the pre-tightening force and improve support effect. It is a new type of material for mine support.

Technical parameters of PC BAR

| Nominal diameter | 7.1mm 9.0mm 10.7mm 12.6mm |

| Production standard | MS1138:PART 3 |

| Tensile strength | ≥ 1420Mpa |

| Yield strength | ≥ 1280Mpa |

| Elongation | ≥ 7.0% |

| Relaxation | ≤ 2.0% |

| Straightness | ≤ 2mm/m |

| Material | 30MnSi , 30Si2Mn , 35Si2Mn , 35Si2Cr |

| Weight per coil | 1ton-2ton |

Prestressing scres- thread bars , PSB400 , PSB830 PSB930 PSB1080

List of main parameters and reference standards of steel bars for prestressed concrete

| Shape | DN(mm) | Tensile strength levels(Mpa) | Slack level(1000h) | standard |

| spiral groove | 6.1,7.1,9.0 10.7 | 1230,1420,1570,1670 | ≤2.5% | JISG3137 |

| ≤2.0% | BG/T5223.3 | |||

| 7.4,9.2,11.0 13.0 | 1230,1420,1570 | ≤1.5% | KSD3505 | |

| smooth-surface | 6.1,7.1,9.0, 10.7 | 1230,1420 1570,1670 | ≤2.5% | JISG3137 |

| ≤2.0% | GB/T5223.3 | |||

| 7.4,9.2,11.0,13.0 | 1230,1420,1570 | ≤1.5% | KSD3505 |

Technical parameter standard(YB/T111-1997)

| Nominal Diameter

mm |

Diameter

mm |

OD allowable deviation

mm |

nominal area

m3 |

theoretical weight

kg/m |

| 7.1 | 7.25 | ±0.15 | 40.0 | 0.314 |

| 9.0 | 9.15 | ±0.20 | 64.0 | 0.502 |

| 10.7 | 11.10 | ±0.20 | 90.0 | 0.706 |

| 12.6 | 13.10 | ±0.20 | 125 | 0.981 |

| Note: The nominal diameter of special-shaped steel bars is equal to the nominal diameter of smooth round steel bars with the same cross-sectional area. | ||||

| Code | Tensile Strength

Mpa |

yield strength(Mpa) | Elongation % | relaxation rate

(%) |

| SBPDL930/1080 | 1080 | 930 | 5 | 2.5 |

| SBPDL1080/1230 | 1230 | 1080 | 5 | 2.5 |

| SBPDL1275/1420 | 1420 | 1275 | 5 | 2.5 |

| Chemical component (%) | P 0.030 S 0.035 Cu 0.30 | |||