ABS Marine Metal Sheet BV Dnv Hot Rolled Vessel Building Material Ah32 Ah36 Dh36 EH36 ASTM A131 Grade A steel sheet Marine Shipbuilding Steel Plate

What is marine grade steel plate?

Marine Grade Steel is a type of structural alloy steel which is standardized by the American Bureau of Shipping (ABS) for specific use in the ship building industry. This group of alloy steel is engineered to be stronger and able to withstand harsh marine conditions.

What are marine grade carbon steels?

There are various Carbon steel grades available such as AH36, DH36, and EH36, that are commonly used in marine environments. These grades have more alloying elements like chromium and manganese that offer more strength and corrosion resistance. These grades are approved by the American Bureau of Shipping.

Product Specification and Steel Grade (For Reference)

| Quality | Testing direction | Material-No. | Yield point Rp0,2 (MPa) | Tensile strength Rm (MPA) | Elongation A80 (in %) min. | r-Value 90° min. | n-Value 90° min. | Old Description |

|---|---|---|---|---|---|---|---|---|

| DC01 | Q | 1.0330 | ≤280 | 270 – 410 | 28 | St 12-03 | ||

| DC03 | Q | 1.0347 | ≤240 | 270 – 370 | 34 | 1,30 | St 13-03 | |

| DC04 | Q | 1.0338 | ≤210 | 270 – 350 | 38 | 1,60 | 0,18 | St 14-03 |

| DC05 | Q | 1.0312 | ≤180 | 270 – 330 | 40 | 1,90 | 0,20 | St 15-03 |

| DC06 | Q | 1.0873 | ≤170 | 270 – 330 | 41 | 2,10 | 0,22 | |

| DC07 | Q | 1.0898 | ≤150 | 250 – 310 | 44 | 2,50 | 0,23 |

| Application | JIS | ASTM | SAE |

| Commercial Quality | G3131 SPHC | A569 A635 A659 A1011 CS Type A, B, C |

1006~1025 |

| Drawing Quality | G3131 SPHD | – | 1006-1010 |

| Deep Drawing Quality | G3131 SPHE | A622 A1011 DS Type A, B |

1006~1010 |

| General Structure (T.S. < 490 N/mm2) |

G3101 SS330 SS400 G3106 SM400A G3132 SPHT1 SPHT2 SPHT3 |

A36 A283 GR.C A570 GR.30~40 A1001 SS GR.30~40 |

1010~1025 |

| General Structure (T.S. ≧ 490 N/mm2) |

G3101 SS490 G3106 SM490A SM490A SM490YA G3132 SPH4 |

A570 GR.45~50 A607 GR.45~70 A1011 SS GR.45, 50 A1011 HSLAS GR.45~70 |

J1392 050X |

Available Size

| Thickness (mm) | Mill Edge Width (mm) |

Cut Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Coil | 1.50~6.50 | 720~1860 | 762 | |

| Coil | 6.51~10.00 | 850~1500 | 762 | |

| Strip | 1.50~6.50 | 30~720 | 762 |

| Thickness (mm) | Mill Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Plate | 6.00~150 | 500~4000 | 1200~18000 |

| Sheet | 1.50~5.99 | 50~1845 | 760~6100 |

Application

Carbon hot rolled steel sheets and plates are used in the welding and construction sectors such as railroad tracks, construction equipment, boom cranes, agriculture equipment and heavy vehicle frames. By varying the percentage in carbon steel, it is possible to produce steel with a variety of different qualities. In general, higher carbon content in steel makes steel harder, brittler and less ductile.

Carbon cold rolled steel coils and strips are produced with a highly adaptable manufacturing process, which are extensively used in automobile, washing machines, refrigerators, electrical appliances and steel office equipment. By varying the percentage in carbon steel, it is possible to produce steel with a variety of different qualities. In general, higher carbon content in steel makes steel harder, brittler and less ductile.

Parameter

| Product | Hot rolled DH36 ABS marine carbon steel plate sheet | Cold rolled AH36 Marine carbon steel plate sheet |

| Thickness | 1.0mm-200mm | 1.0mm-6.0mm |

| Standard Width | 1000mm/1200mm/1500mm/1800mm/2000mm/2200mm | 1000mm/1219mm/1500mm |

| Standard Length | 2000mm/2438mm/4000mm /6000mm 8000mm 12000mm or as client’s requirement | 2000mm/2439mm/3000mm or as per client’s requirement |

| Standard | ABS ASTM,JIS,SUS,GB,DIN | ASTM,JIS,SUS,GB,DIN |

| Packing | Standard export packing for marine Carbon steel sheet:

1.surface , 2: bundle package, 3:wooden case,wooden pallet package, 4:container or bulk, 5:special according to customer’s request |

|

| Application | ABS Marin carbon Steel Sheet are widely used in below fields:

AH36, DH36, and EH36, that are commonly used in marine environments. These grades have more alloying elements like chromium and manganese that offer more strength and corrosion resistance. These grades are approved by the American Bureau of Shipping . ABS grades are used in the Ship Building(Marine) and mobile offshore drilling units and structures. |

|

What are the materials of marine steel plates and their applications in shipbuilding?

Marine steel plate is a special steel plate material that is used exclusively for shipbuilding. As ships are used in the marine environment, they need to have good weather resistance, corrosion resistance and high strength, etc. Therefore, the material selection of marine steel plate and its application is crucial. In this paper, we will elaborate on the two aspects of the material of marine steel plate and its application in shipbuilding.

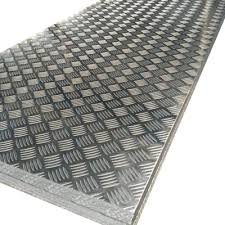

There are many kinds of materials of marine steel plate, and the common ones are common ship plate steel, light ship plate steel, high strength ship plate steel, etc. Among them, common ship plate steel is the most important one. Among them, ordinary plate steel is one of the most commonly used marine steel materials, its mechanical properties are better, with a certain degree of elasticity and toughness. Light ship plate steel is relatively light, the weight can not only reduce the hull load, but also improve the ship’s cargo carrying capacity. High-strength ship plate steel, on the other hand, has excellent strength and toughness, which can make the hull more robust and durable.

In shipbuilding, marine steel plate is widely used. First of all, it is the inner and outer wall plate of the ship hull. As the main component material of the hull, marine steel plate is used to make the inner and outer wall plate of the hull, which can ensure the overall strength and stability of the hull. Secondly, it is the bottom plate and deck of the ship. Marine steel plate is used to make the bottom plate and deck of the hull, which can withstand the huge pressure from seawater and cargo to ensure the safe navigation of the ship. In addition, marine steel plate is also used in the ship’s bulkheads and ship equipment support structure and other parts of the ship, play a load-bearing and support role.

The selection of marine steel plate material is related to different parts of shipbuilding and the use of the ship. For example, high yield strength ship plate steel is suitable for the main components of the ship’s hull and high load-bearing parts, which can improve the strength and stability of the ship’s hull. As for the parts with high demand for preventing corrosion and rust, such as the outer wall plate of the hull and the bottom plate of the ship, stainless steel plate with good corrosion resistance is usually chosen as the ship steel plate material. In addition, with the continuous development of shipbuilding technology, a new type of marine steel plate material has emerged, namely, composite ship plate steel. The material adopts multi-layer composite structure, which can meet the technical requirements of different parts and make the ship lighter and stronger.

To summarize, the material selection of marine steel plate and its application in shipbuilding are of great significance. There are many kinds of materials of marine steel plate, and different hull parts and applications need to choose different materials to ensure the safety and reliability of the ship. Marine steel plate is widely used in shipbuilding, covering key parts of the hull such as inner and outer wall plates, bottom plates and decks, which play the role of load-bearing and support. With the progress of shipbuilding technology, marine steel plate materials are also constantly innovating and developing, playing an important role in improving ship performance and safety.

USES OF STEEL IN SHIPBUILDING

Modern shipbuilding steel plate is well suited for the manufacturing of boats, ships, marine vessels, and other structures, as it is light in weight, high in tensile strength, and better in corrosion resistance than any other traditional shipbuilding steel plate, making it much better for more efficient construction. Most of the offshore and marine structures are created using carbon and alloy steel plates. Ship hulls, upper decks, bulkheads, anchor chains, bulk carriers, as well as container ships all rely on the material properties of these shipbuilding steels.

USES OF STEEL IN MARINE ENGINEERING PROJECTS

In addition to this, steels also play a decisive role in marine engineering projects, and they can be found everywhere as they involve offshore oil platforms, piers, and vessels. Steel with alloying elements enhanced its durability as well as anti-rust and anti-corrosion capability. Structures last longer when made from special steels grade, and they can resist the corrosion that is often found in other steel or alternative materials.

Wisdom SOLUTIONS FOR MARINE ENGINEERING INDUSTRY

Wisdom metal provides a wide range of quality shipbuilding and marine engineering steel types such as steel plates, steel sections, and a variety of special steels, applicable for shipbuilding, drill pipe, anchor chain, offshore oil platform, etc. We strive to provide marine and offshore steel under the most stringent approval of the production methods of classification societies in different countries, focusing on resistance to marine corrosion steel products for your needs.

Wisdom metal has provided a wide variety of well-established steel service centers and end-users in the ocean engineering sector with reliable steel products for over a decade. We have established long-term cooperative relations with hundreds of mills to ensure these products are fabricated using premium material and are in sync with various international standards.