Product description:

A beam is a structural element that supports a building or structure. It can be either primary support or secondary support and is generally used to bear a load from some other member, such as a foundation or the outer walls.

Beams are classified by their shapes (I-beams, L-beams, box beams) and sizes (2×4, 2×6). They’re also classified by their material and how they’re attached to the structure of the building. Beams are generally made from wood, steel or concrete. In addition to these materials, some beams can be made with bamboo or balsa wood as well.

Beams are often used when constructing buildings because they allow for easy installation of wiring and piping without having to worry about overworking any one part of the building too much.

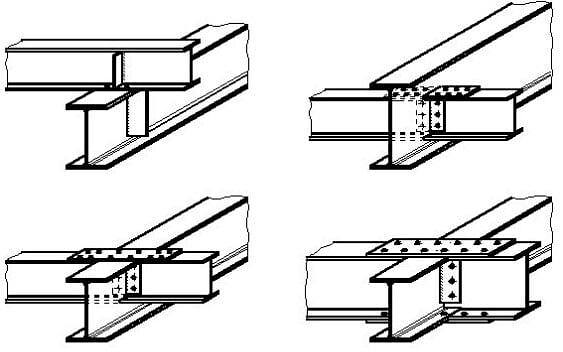

The inner and outer sides of the flange of H-shaped steel are parallel or nearly parallel, and the end of the flange is at right angles, so it is named parallel flange I-beam. The web thickness of H-shaped steel is smaller than that of ordinary I-beam with the same height as the web, and the flange width is larger than that of ordinary I-beam with the same height as the web, so it is also called wide edge I-beam. Determined by the shape, the section modulus, inertia moment and corresponding strength of H-beam are obviously better than those of ordinary I-beam with the same single weight. When used in metal structures with different requirements, it shows its superior performance in terms of bending moment, pressure load and eccentric load. It can greatly improve the bearing capacity and save 10% ~ 40% of metal compared with ordinary I-beam. H-shaped steel has wide flange, thin web, many specifications and flexible use. It can save 15% ~ 20% of metal when used in various truss structures. Because the inner and outer sides of the flange are parallel and the edge ends are at right angles, it is convenient to assemble and assemble various components, which can save about 25% of the welding and riveting workload, greatly accelerate the construction speed of the project and shorten the construction period.

| Material | A36、St37、St52,16Mn,S235J0、S235J2,S235JR,S355JR,S355,S355J0SS440,SM400A,SM400BQ195,Q235B,Q355B, |

| Production Range | A572,GR50,GR60,SS540H100*100-H400*400H150*75 -H900*300 |

| Standard | ASTM A36;ASTM A6(W);ASTM A6(S);JIS 3192;JIS 3136;EN10034;EN10163;EN10025-2;AS/NZS3679.1; |

| Length | 6m, 9m, 12m or as customer requirement |

| Technology | Hot rolled,welded |

| Surface | Galvanized, paint;or as your request |

| Supply ability | 2000Ton/day |

| Business type | Manufacturer |

| Certification: | ISO, SGS,BV |

| Application | widely used in building structure and engineering construction, such as room beam,ship beam, industrial furnace, etc. |

| Loading port | any port in China |

| Packing | standard export packing or as your requirement |

| Payment Terms | T/T, L/C at sight,West Union,D/P,D/A,Paypal |

| Brand name |

WISDOM STEEL |

|||

| Products name | hot rolled H-beam hot dipped galvanized structural steel h beam Welded H steel beam section profile | |||

| Material | Q235B, Q345B, Q255, Q275, SS400, A36, SM400A, St37-2, SA283Gr, S235JR, S235J0, S235J2 | |||

| Standard |

ASTM, AISI, JIS, GB, DIN, EN |

|||

| length |

6M, 12M, or As required |

|||

| price terms | FOB, CRF, CIF, EXW all acceptable | |||

| Packing | Carbon steel is bare packaging; Other material is standard export packing (inside: water proof paper, outside:steel covered with strips and pallets). |

|||

| Country of Origin | CHINA | |||

| European standard I-beam theoretical weight specification table | |||||

| Specification | height | width | web thickness | wing thickness | theoretical weight |

| IPE80 | 80 | 46 | 3.8 | 5.2 | 6 |

| IPE100 | 100 | 55 | 4.1 | 5.7 | 8.1 |

| IPE120 | 120 | 64 | 4.4 | 6.3 | 10.4 |

| IPE140 | 140 | 73 | 4.7 | 6.9 | 12.9 |

| IPE160 | 160 | 82 | 5 | 7.4 | 15.8 |

| IPE180 | 180 | 91 | 5.3 | 8 | 18.8 |

| IPE200 | 200 | 100 | 5.6 | 8.5 | 22.4 |

| IPE220 | 220 | 110 | 5.9 | 9.2 | 26.2 |

| IPE240 | 240 | 120 | 6.2 | 9.8 | 30.7 |

| IPE270 | 270 | 135 | 6.6 | 10.2 | 36.1 |

| IPE300 | 300 | 150 | 7.1 | 10.7 | 42.2 |

| IPE330 | 330 | 160 | 7.5 | 11.5 | 49.1 |

| IPE360 | 360 | 170 | 8 | 12.7 | 57.1 |

| IPE400 | 400 | 180 | 8.6 | 13.5 | 66.3 |

| IPE450 | 450 | 190 | 9.4 | 14.6 | 77.6 |

| IPE500 | 500 | 200 | 10.2 | 16 | 90.7 |

| IPE550 | 550 | 210 | 11.1 | 17.2 | 106 |

| IPE600 | 600 | 220 | 12 | 19 | 122 |

H Steam

H-section steel is a kind of economical section and high-efficiency section with more optimized cross-sectional area distribution and more reasonable strength-to-weight ratio. It is named because its section is the same as the English letter “H”. Since the various parts of the H-shaped steel are arranged at right angles, the H-shaped steel has the advantages of strong bending resistance, simple construction, cost saving and light structure in all directions.

HE-B steel beam, also called H-beam. The H-beam is square with equal height and width.

The construction provides the beam with great strength and rigidity. The form of the beam prevents bending of the transverse parts.

A steal beam is suitable for both indoor and outdoor use. However, it will rust over time, when it is exposed to the humidity of the air. Therefore, it rusts faster outdoor. If you would like to encourage the corrosion process, water can be added.

The steel H-steel beam can be used for enforcement of tiers of beams, poles, a bearer over a door or window, etc.

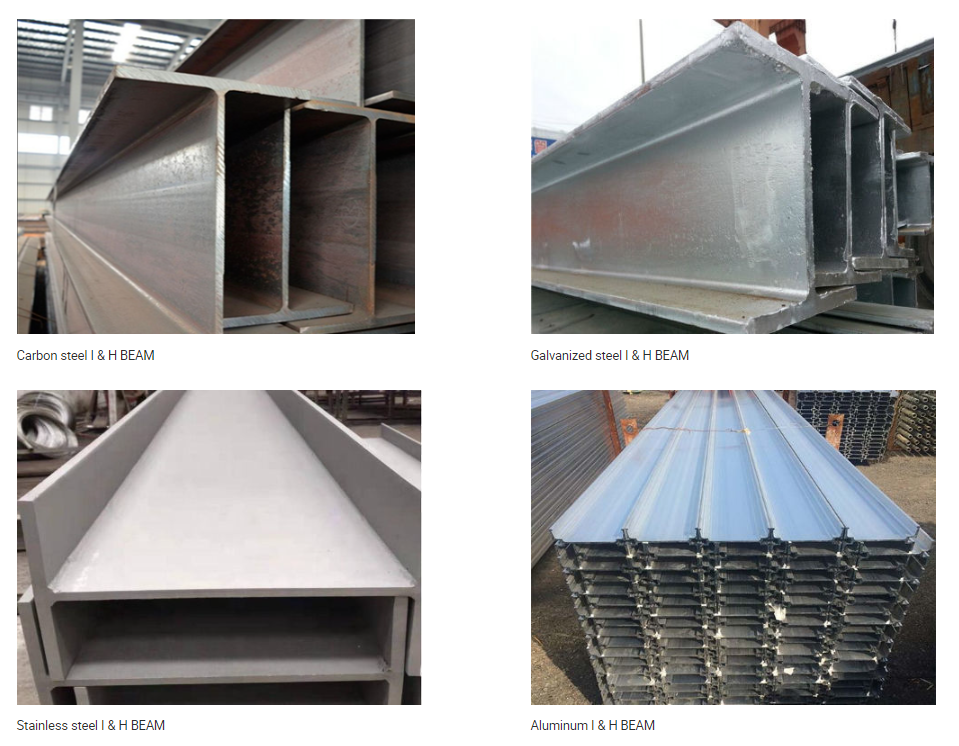

- Pipe Type:Structural H Beam,H Beam ,H section,Carbon Steel H-beam,Stainless Steel H-beam,

Galvanized H Beam,Aluminum H Beam,Alloy H Beam,Wide Flange Beam,High-Spec H-Beams,Patterned H-Beams

Size:100*50-700*300mm

Web Thickness:5-16mm

Web Width:50–300mm

Flange Thickness:4.5-23mm

Flange Width:50-400mm

Length:1-12m or as customer request

Standard:AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,BS ISO.etc

Shape:H Channel/I Channel

Technique:Hot rolled/Cold Rolled/Galvanized

Edge:Mill Edge/ Silt Edge

Surface Treatment:Hot Dip Galvanized, Painting or Black.

Application:Construction,Decoration,Ship,Medical Equipment,Machinery,Mechanical&manufacture,Steel structure,Shipbuilding,Bridging, Automobile chassis

Steel Grade:

1015,1020,1035,1045,1055,1060,1213,1140,1215,9255,9262,1039,1025,1335,1330,1050,1095,4520,2515,3135,3415,3310,9840,8620,8740,4340,5015,5132,5140,5115,5155,4130,4137,4135,4140,

4142,6150,Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 12Cr1MoV Cr5Mo

15CrMo 30CrMo 40CrMo 20SiMn 12Cr1MoVG 20CrNiMo 15CrMoG A3642CrMo 40CrNiMoA 50CrV

Stainless steel H-beam:

Length:1-12m or as customer’s request

height:100-1000mm

Width:100-407mm

Thickness:4.0mm-35mm

Tolerance:±0.05mm

Standard:AISI,ASTM,DIN,JIS,GB ,JIS,SUS,EN,etc

Technique:Hot rolled / cold rolled

Surface Treatment:No.1/No.3/No.4/HL/1D/8K

Material:201, 202, 301, 302, 303, 304, 304L, 304H, 310S, 316, 316L, 317L, 321,310S,309S, 410, 410S,420, 430, 431, 440A,904L

Application:Mechanical&manufacture,Steel structure,Shipbuilding,Bridging, Automobile chassisCarbon Steel H-beam:

Height:100-900mm

Width:50-400mm

Web thickness:5-30mm

Flange thickness:7-40mm

Standard:ASTM,AISI,JIS,DIN,EN,BS

Processing Type:Cutting, bending,stamping,welding,cnc machining

Cutting Type :Laser cutting;water-jet cutting;flame cutting

Surface Treatment:1),Bared2),Black painted (varnish coating)3),Galvanized4),With oiled-covered

Application:Construction,Decoration,Ship,Medical Equipment,Machinery,etc

Technique:Hot Rolled Edge:Mill Edge/ Silt Edge

Grade:1015,1020,1035,1045,1055,1060,1213,1140,1215,9255,9262,1039,1025,1335,1330,1050,1095,4520,2515,3135,3415,3310,9840,8620,8740,4340,5015,5132,5140,5115,5155,4130,4137,4135,4140,

4142,6150,Ck10,Ck15,Ck22,Ck25,Ck30,Ck35,Ck40,Ck45,Ck50, 30Mn4,40Mn4 12Cr1MoV Cr5Mo

15CrMo 30CrMo 40CrMo 20SiMn 12Cr1MoVG 20CrNiMo 15CrMoG A3642CrMo 40CrNiMoA 50CrV

Sepcification

-

Wide Flange Series

Classification

(Height × Flange width)Standard cross-section

dimensions (mm)Cross-sectional

area(cm3)Unit mass

(kg/m)H×B t1 t2 r 100×100 *100×100 6

8

8

21.59 16.9 125×125 125×125 6.5

9

8

30.00 23.6 150×150 150×150 7

10

8

39.65 31.1 175×175 175×175 7.5

11

13

51.43 40.4 200×200 200×200

*200×2048

1212

1213

1363.53

71.5349.9

56.2250×250 *244×252

250×250

*250×25511

9

1411

14

1413

13

1381.31

91.43

103.963.8

71.8

81.6300×300 *294×302

300×300

*300×30512

10

1512

15

1513

13

13106.3

118.5

133.483.4

93.0

105.0350×350 *344×348

*344×354

350×35010

16

1216

16

1913

13

13144.0

164.6

171.9113.0

129.0

135.0400×400 400×400 13

21

22

218.7 172.0 Classification

(Height × Flange width)Reference Second moment

of area(cm4)Radius of gyration

of area(cm)Section

modulus(cm3)lx ly ix iy zx zy 100×100 378 134 4.18 2.49 75.6 26.7 125×125 839 293 5.29 3.13 134.0 46.9 150×150 1,620 563 6.40 3.77 216.0 75.1 175×175 2,900 984 7.50 4.37 331.0 112.0 200×200 4,720

4,9801,600

1,7008.62

8.355.02

4.88472.0

498.0160.0

167.0250×250 8,700

10,700

11,4002,940

3,650

3,88010.30

10.80

10.506.01

6.32

6.11713.0

860.0

912.0233.0

292.0

304.0300×300 16,600

20,200

21,3005,510

6,750

7,10012.50

13.10

12.607.20

7.55

7.301,130.0

1,350.0

1,420.0365.0

450.0

466.0350×350 32,800

34,900

39,80011,200

11,800

13,60015.10

14.60

15.208.84

8.48

8.891,910.0

2,030.0

2,280.0646.0

669.0

776.0400×400 66,600 22,400 17.50 10.10 3,330.0 1,120.0 Medium Flange Series

Classification

(Height × Flange width)Standard cross-section

dimensions(mm)Cross-sectional

area(cm3)Unit mass

(kg/m)H×B t1 t2 r 200×150 194×150 6

9

8

38.11 29.9 250×175 244×175 7

11

13

55.49 43.6 300×200 294×200 8

12

13

71.05 55.8 350×250 340×250 9

14

13

99.53 78.1 400×300 390×300 10

16

13

133.30 105 450×300 440×300 11

18

13

153.90 121 500×300 482×300

488×30011

1115

1813

13141.2

159.2111

125600×300 582×300

588×300

594×30212

12

1417

20

2313

13

13169.20

187.20

217.10133

147

170700×300 692×300

700×30013

1320

2418

18207.50

231.50163

182800×300 792×300

800×30014

1422

2618

18239.50

263.50188

207900×300 *890×299

900×300

*912×30215

16

1823

28

3418

18

18266.90

305.80

360.10210

240

283Classification

(Height × Flange width)Reference Second moment

of area(cm4)Radius of gyration

of area(cm)Section

modulus(cm3)lx ly ix iy zx zy 200×150 2,630 507 8.30 3.65 271 67.6 250×175 6,040 984 10.40 4.21 495 112 300×200 11,100 1,600 12.50 4.75 756 160 350×250 21,200 3,650 14.60 6.05 1,250 292 400×300 37,900 7,200 16.90 7.35 1,940 480 450×300 54,700 8,110 18.90 7.26 2,490 540 500×300 58,300

68,9006,760

8,11020.30

20.806.92

7.142,420

2,820450

540600×300 98,900

114,000

134,0007,660

9,010

10,60024.20

24.70

24.806.73

6.94

6.983,400

3,890

4,500511

601

700700×300 168,000

197,0009,020

10,80028.50

29.206.59

6.834,870

5,640601

721800×300 248,000

286,0009,920

11,70032.20

33.006.44

6.676,270

7,160661

781900×300 339,000

404,000

491,00010,300

12,600

15,70035.60

36.40

36.906.20

6.43

6.597,610

8,990

10,800687

842

1.040Narrow Flange Series

Classification

(Height × Flange width)Standard cross-section

dimensions(mm)Cross-sectional

area(cm3)Unit mass

(kg/m)H×B t1 t2 r 200×100 *198×99

200×1004.5

5.57

88

822.69

26.6717.8

20.9250×125 248×124

250×1255

68

98

831.99

36.9725.1

29.0300×150 298×149

300×1505.5

6.58

913

1340.80

46.7832.0

36.7350×175 346×174

350×1756

79

1113

1352.45

62.9141.2

49.4400×200 396×199

400×2007

811

1313

1371.41

83.3756.1

65.4450×200 446×199

450×2008

912

1413

1382.97

95.4365.1

74.9500×200 496×199

500×200

*506×2019

10

1114

16

1913

13

1399.29

112.30

129.3077.9

88.2

102.0600×200 596×199

600×200

*606×20110

11

1215

17

2013

13

13117.80

131.70

149.8092.5

103.0

118.0Classification

(Height × Flange width)Reference Second moment

of area(cm4)Radius of gyration

of area(cm)Section

modulus(cm3)lx ly ix iy zx zy 200×100 1,540

1,810113

1348.25

8.232.24

2.24156

18122.9

26.7250×125 3,450

3,960255

29410.40

10.402.82

2.82278

31741.1

47.0300×150 6,320

7,210442

50812.40

12.403.29

3.29424

48159.3

67.7350×175 11,000

13,500791

98414.50

14.603.88

3.96638

77191.0

112.0400×200 19,800

23,5001,450

1,74016.60

16.804.50

4.56999

1.170145.0

174.0450×200 28,100

32,9001,580

1,87018.40

18.604.36

4.431,260

1,460159.0

187.0500×200 40,800

46,800

55,5001,840

2,140

2,58020.30

20.40

20.704.31

4.36

4.461,650

1,870

2,190185.0

214.0

256.0600×200 66,600

75,600

88,3001,980

2,270

2,72023.80

24.00

24.304.10

4.16

4.262,240

2,520

2,910199.0

227.0

270.0High-Spec H-Beams

Standard Type code Chemical composition Unit:(%) Unit:(%) Spec code C

(max.)Si

(max.)Mn P

(max.)S

(max.)Cu

(max.)Cr*6

(max.)Sn

(max.)Ceq Pcm JIS G 3101 SS400

–

–

–

0.050

0.050

–

–

–

–

–

YHS-SS400

0.20

0.35

0.80 or lower

0.030

0.015

0.40

0.25

0.040

0.36

or lower–

JIS G 3136 SN400B

0.20

0.35

0.60 – 1.40

0.030

0.015

–

–

–

0.36

or lower(0.26 or lower) *4

YHS-SN400B

0.20

0.35

0.60 – 1.40

0.030

0.015

0.40

0.25

0.040

0.36

or lower0.26 or lower

JIS G 3106 SM490A

0.20

0.55

1.65 or lower

0.035

0.035

–

–

–

–

–

YHS-SM490A

0.18

0.40

1.50 or lower

0.030

0.013

0.40

0.25

0.035

0.44

or lower0.29 or lower

JIS G 3136 SN490B

0.18

0.55

1.60 or lower

0.030

0.015

–

–

–

0.44

or lower(0.29 or lower) *4

YHS-SN490B

0.18

0.40

1.50 or lower

0.030

0.013

0.40

0.25

0.035

0.44

or lower0.29 or lower

Standard Type code Mechanical properties Shape/

Dimensional

standardProduct’s internal

propertiesSpec code Yield point *1

(N/mm2)Tensile

strengthYield

ratio *2Elongation(%) Impact

value(0℃)*3Steel

thickness(mm)(N/mm2) (N/mm2) (%) Steel

thickness(mm)(%) (J) JIS G 3101 SS400

t≦16

245

or higher400 – 510

–

5<t≦16

17

or higher–

JIS G 3192

16<t≦40

235

or higher16<t≦50

21

or higherYHS-SS400

245 – 355

400 – 510

–

21 or higher

27

or higherJIS G 3136 SN400B

6≦t<12

235

or higher400 – 510

80

or lower6≦t≦16

18

or higher27

or higherJIS G 3136

12≦t≦40

235 – 355

16<t≦50

22

or higherYHS-SN400B

235 – 355

400 – 510

80

or lower22 or higher

70

or higher*5 JIS G 3106 SM490A

t≦16

325

or higher490 – 610

–

5<t≦16

17

or higher–

JIS G 3192

16<t≦40

315

or higher16<t≦50

21

or higherYHS-SM490A

325 – 445

490~610

80

or lower21 or higher

70

or higher*5 JIS G 3136 SN490B

6≦t<12

325

or higher490 – 610

80

or lower6≦t≦16

17

or higher27

or higherJIS G 3136

12≦t≦40

325 – 445

16<t≦50

21

or higherYHS-SN490B

325 – 445

490 – 610

80

or lower21 or higher

100

or higher*5 Patterned H-Beams

Deck type Surface pattern Name Material type Yamato Deck Circular dot pattern

YDB(Yamato Deck Beam)

SM490A type

General Deck Grid pattern

YSB(Yamato Striped Beam)

◆Cross-section dimensions, cross-sectional area, unit mass and characteristicsName Cross-section dimensions(mm) Cross-sectional

area(cm2)Unit mass

(kg/m)H×B t1 t2 r YDB

191.5×197 5.8 7.8(8.2) 13 44.27 34.7 YSB

196×197 6 8 13 47.39 37.2 Name Second moment of

area(cm4)Radius of gyration

of area(cm)Section modulus

(cm3)lx ly ix iy zx zy YDB

3,120 1,040 8.40 4.85 322 106 YSB

3,408 1,165 8.48 4.96 348 118 ◆Chemical composition

(Chemical composition and mechanical properties are the same for YDB and YSB)C Si Mn P S 0.20% or lower 0.55% or lower 1.65% or lower 0.035% or lower 0.035% or lower ◆Mechanical propertiesYield point and proof strength Tensile strength Elongation 325N/mm2 or higher 490~610N/mm2 17% or higher

Production Process

H-Beam and I-Beam: Applications

H-Beams and I-beams are very similar, but they have different applications. If you’re interested in using either of them for your next project, here’s what you need to know:

- The best way to determine which beam is best for your project is to consult a professional. H-beams are better suited to support the load of the floor and roof over longer distances, while i-beams are better suited to support the weight of a wall or column.

- If you do decide on an H-beam or an I-beam, note that these beams have different minimum spans; this means that if your space has a large span (i.e., it’s long), then an I-beam may not be right for it because it requires more material than other designs.