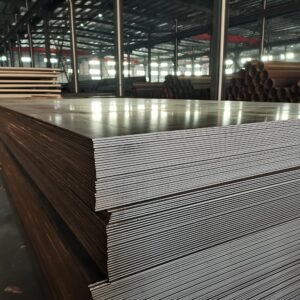

ASTM SA516Gr70(HIC) S355J2 American Standard S355J0WP corten A S355J2W corten B Hydrogen Resistant Plate ABS Hot Rolled ASTM 09MnNiDR Low Temperature Container Plate

What is carbon steel plate?

Carbon steel plates are made from an alloy comprised of iron and carbon. Carbon Steel Plate is one of the most commonly used steels in the United States. Alloy steels can contain a variety of elements including chromium, nickel, and vanadium.

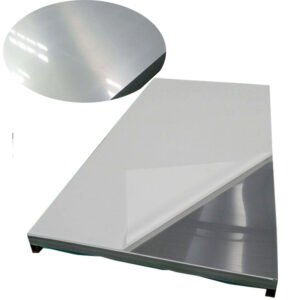

Cold rolled steel sheet Low Carbon Steel plate-St12 Steel Plate

This product list describes a portfolio of hot-rolled steel plates designed for three primary extreme service environments: hydrogen resistance, atmospheric corrosion resistance (weathering), and low-temperature containment. These are specialized steels used in critical applications across the petrochemical, architectural, and energy sectors.

Detailed Breakdown by Category

1. Hydrogen Resistant Steels (For Sour Service)

These plates are engineered to resist failure in environments containing wet hydrogen sulfide (H₂S), a common condition in oil and gas refining known as “sour service.”

-

ASTM SA516 Gr70 (HIC):

-

Standard: ASTM A516

-

Description: This is a carbon steel plate for pressure vessels. The “(HIC)” suffix is crucial, indicating it has been manufactured with special melting practices and testing to be Resistant to Hydrogen-Induced Cracking (HIC) and Sulfide Stress Cracking (SSC). HIC occurs when atomic hydrogen diffuses into the steel and forms internal blisters or cracks.

-

Application: Pressure vessels, reactors, and separators in oil refineries, petrochemical plants, and gas processing facilities where “sour” (H₂S-containing) hydrocarbons are present.

-

-

Hydrogen Resistant Plate:

-

This is a general term for plates meeting the requirements of standards like NACE MR0175/ISO 15156, which govern materials for sour service. SA516 Gr70 (HIC) is a prime example.

-

-

ABS Hot Rolled:

-

Standard: American Bureau of Shipping (ABS)

-

Description: This indicates the steel plate is certified by the ABS classification society for use in shipbuilding. For hydrogen service, this would likely be an ABS-grade steel (e.g., ABS Grade A through F) specified with additional HIC testing requirements.

-

Application: Ship hulls, offshore structures, and marine cargo tanks that may carry sour crude oil or other corrosive cargos.

-

2. Atmospheric Corrosion Resistant Steels (Weathering Steel)

These steels, commonly known as “weathering steel,” form a dense, stable oxide layer (patina) upon exposure to the atmosphere. This adhesive layer protects the underlying metal, eliminating the need for painting in many applications.

-

S355J0WP & S355J2W:

-

Standard: EN 10025-5 (European Standard)

-

Description: These are structural steels with improved atmospheric corrosion resistance.

-

S355 indicates a minimum yield strength of 355 MPa.

-

J0 and J2 indicate impact toughness tested at 0°C and -20°C, respectively.

-

W stands for “Weathering.”

-

P stands for “Plate.”

-

-

Application: Architectural building facades, bridges, un-painted structural components, and artistic sculptures.

-

-

Corten A & Corten B:

-

Standard: ASTM A242 (Corten A) / ASTM A588 (Corten B)

-

Description: These are the classic, proprietary U.S. grades for high-strength low-alloy weathering steel. “Corten” is a well-known trademark.

-

Corten A is typically used for sheet and architectural applications.

-

Corten B is a tougher grade more commonly supplied as plate for structural applications like bridges.

-

-

Application: Similar to the S355JxW grades, used extensively in exposed architecture, bridge construction, and outdoor sculpture.

-

3. Low Temperature Container Plate

This steel is designed to maintain high toughness and resist brittle fracture at very low (cryogenic) temperatures.

-

ASTM A/SA 09MnNiDR:

-

Standard: ASTM A/SA 841 (a standard specification for steel plates for pressure vessels)

-

Description: This is a fine-grain, normalized (or normalized-rolled) carbon-manganese-nickel steel plate. The “DR” stands for “Low Temperature”.

-

The “09” indicates a low carbon content (~0.09% max).

-

The “MnNi” indicates alloying with Manganese and Nickel, which greatly enhances low-temperature toughness.

-

It is typically used for service temperatures down to -70°C (-94°F).

-

-

Application: Pressure vessels for the storage and transportation of liquefied gases (LPG, LNG, ammonia, etc.), cryogenic storage tanks, and other equipment operating at low temperatures.

-

Summary Table of Applications

| Steel Grade / Category | Primary Characteristic | Typical Application |

|---|---|---|

| SA516 Gr70 (HIC) | Resistance to Hydrogen-Induced Cracking | Refinery pressure vessels, sour gas scrubbers |

| S355J0WP / S355J2W | Atmospheric Corrosion Resistance | Architectural structures, bridges, containers |

| Corten A / Corten B | Atmospheric Corrosion Resistance | Building cladding, bridges, outdoor art |

| 09MnNiDR | Excellent Low-Temperature Toughness (down to -70°C) | Cryogenic storage tanks, LPG/LNG carriers |

In essence, this product list represents a specialized supplier capable of providing steel plates for some of the most challenging engineering environments, from the corrosive depths of oil refineries to the artistic and architectural expression of modern buildings and the frigid conditions of cryogenic storage.

The properties of carbon steel are high hardness, strength, wear resistance and anti-corrosion.

Carbon steel is an alloy with carbon and iron, with carbon content up to 2.1% by weight. The increase in the carbon percentage will raise steel’s hardness and strength, but it will be less ductile. Carbon steel has good properties in hardness and strength, and it is less expensive than other steels.

Hot Rolled Q235 Q195 A36 ST37 Iron Metal Sheet Carbon Steel Plate Marine Shipbuilding Steel Plate

Product Specification and Steel Grade (For Reference)

| Quality | Testing direction | Material-No. | Yield point Rp0,2 (MPa) | Tensile strength Rm (MPA) | Elongation A80 (in %) min. | r-Value 90° min. | n-Value 90° min. | Old Description |

| DC01 | Q | 1.0330 | ≤280 | 270 – 410 | 28 | St 12-03 | ||

| DC03 | Q | 1.0347 | ≤240 | 270 – 370 | 34 | 1,30 | St 13-03 | |

| DC04 | Q | 1.0338 | ≤210 | 270 – 350 | 38 | 1,60 | 0,18 | St 14-03 |

| DC05 | Q | 1.0312 | ≤180 | 270 – 330 | 40 | 1,90 | 0,20 | St 15-03 |

| DC06 | Q | 1.0873 | ≤170 | 270 – 330 | 41 | 2,10 | 0,22 | |

| DC07 | Q | 1.0898 | ≤150 | 250 – 310 | 44 | 2,50 | 0,23 |

| Application | JIS | ASTM | SAE |

| Commercial Quality | G3131 SPHC | A569 A635 A659 A1011 CS Type A, B, C |

1006~1025 |

| Drawing Quality | G3131 SPHD | – | 1006-1010 |

| Deep Drawing Quality | G3131 SPHE | A622 A1011 DS Type A, B |

1006~1010 |

| General Structure (T.S. < 490 N/mm2) |

G3101 SS330 SS400 G3106 SM400A G3132 SPHT1 SPHT2 SPHT3 |

A36 A283 GR.C A570 GR.30~40 A1001 SS GR.30~40 |

1010~1025 |

| General Structure (T.S. ≧ 490 N/mm2) |

G3101 SS490 G3106 SM490A SM490A SM490YA G3132 SPH4 |

A570 GR.45~50 A607 GR.45~70 A1011 SS GR.45, 50 A1011 HSLAS GR.45~70 |

J1392 050X |

Available Size

| Thickness (mm) | Mill Edge Width (mm) |

Cut Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Coil | 1.50~6.50 | 720~1860 | 762 | |

| Coil | 6.51~10.00 | 850~1500 | 762 | |

| Strip | 1.50~6.50 | 30~720 | 762 |

| Thickness (mm) | Mill Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Plate | 6.00~150 | 500~4000 | 1200~18000 |

| Sheet | 1.50~5.99 | 50~1845 | 760~6100 |

Application

Carbon hot rolled steel sheets and plates are used in the welding and construction sectors such as railroad tracks, construction equipment, boom cranes, agriculture equipment and heavy vehicle frames. By varying the percentage in carbon steel, it is possible to produce steel with a variety of different qualities. In general, higher carbon content in steel makes steel harder, brittler and less ductile.

Carbon cold rolled steel coils and strips are produced with a highly adaptable manufacturing process, which are extensively used in automobile, washing machines, refrigerators, electrical appliances and steel office equipment. By varying the percentage in carbon steel, it is possible to produce steel with a variety of different qualities. In general, higher carbon content in steel makes steel harder, brittler and less ductile.

Parameter

| Product | Hot rolled carbon steel plate sheet or coil | Cold rolled carbon steel plate sheet or coil |

| Thickness | 3.0mm-200mm | 0.3mm-6.0mm |

| Standard Width | 1240mm/1500mm/1800mm/2000mm/2200mm | 1000mm/1219mm/1500mm |

| Standard Length | 2438mm/6000mm or as client’s requirement | 2000mm/2439mm/3000mm or as per client’s requirement |

| Standard | ASTM,JIS,SUS,GB,DIN | ASTM,JIS,SUS,GB,DIN |

| Packing | Standard export packing for stainless steel sheet:1.surface polish,2: bundle package,3:wooden case,wooden pallet package,4:container or bulk,5:special according to customer’s request | |

| Application | carbon Steel Sheet are widely used in below fields:1.Construction field,shipping building industry2.Petroleum and Chemical Industries3.Food and Mechanical Industries4.Boiler Heat Exchange5.Machinery and Hardware Industries | |