TFS Structure

Generally, it is believed that the tin free steel (TFS) is composed of four layers, including steel base, metallic chromium layer, chromium oxide layer and oil film, as shown below.

Function of Each Layer of TFS:

①The role of steel base is similar to that of ETP, which ensures the formability of TFS usage and machining and provides strength of finished products;

②Metallic chromium layer has strong passivation capability and good corrosion resistance, but as it is cathodic coating, it can only provide mechanical protection for steel base. Besides, due to strong passivation capability of metallic chromium, an extremely thin layer of passivation film is easy to produce (chromium oxide);

③Chromium oxide layer has relatively high chemical stability, and the electrode potential of the film is more positive than that of iron. When surrounded by ordinary corrosive media, it is cathodic coating, requiring coating to protect the contents. As an amorphous layer, the layer can close pores of the metallic chromium layer and provide excellent coating adhesion;

④The role of the oil film is similar to that of ETP, and its lubrication is better than that of ETP, for tin itself is of lubricity.

Production Process and Equipment Features of TFS Line

Baosteel’s TFS line adopts the two-step process, the major steps of which include:

Uncoiling → Alkaline cleaning → Straightening → Pickling → Metallic chromium plating → Chromium oxide plating → Oiling → Side cutting → Quality inspection → Coiling

Process Equipment Features of TFS Line

①The tension straightening machine can effectively improve plate shapes;

②“The two-step chrome-plating process can effectively control both the metallic chromium thickness and the chromium oxide thickness;

③Electrostatic oiling ensures a uniform oiling result;

④The surface color of Baosteel TFS is blue, which is preferred by users for applications;

⑤It is equipped with the online defect identification system.

| Product name | JIS G3315 Temper Paint Can MR T4 CA/BA Prime Electrolytic Tin Free Steel Plate Sheet Supplier MR Grade TFS Coil Tinplate sheet |

| Material | ASTM A653, DX51D, Q195 ,DC01DX51D+Z, DX52D+Z , DX53D+Z ,DX54D+Z ,DX56D+ZHC1030 1300MS, HC1150 /1400MS, HC1200/1DC51D+Z , DC52D+Z, DC53D+Z, DC54D+Z ,DC56D+Z, H220PD+Z,H260PD+Z, H300LAD+Z,H340LAD+Z , H380LAD+ZSGCC CSTYPEB, SCGA2370D, SCG270E, SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+ZEN 10142,EN 10147,EN 10292,JIS G3302, ASTM A653/A653M, BQB 420 |

| Zinc Coating | 20-275g/m2 |

| Thickness | 0.13-200mm |

| Width | 100-4000 mm ,As customer’s requirement |

| length | 1000-12000mm ,As customer’s requirement |

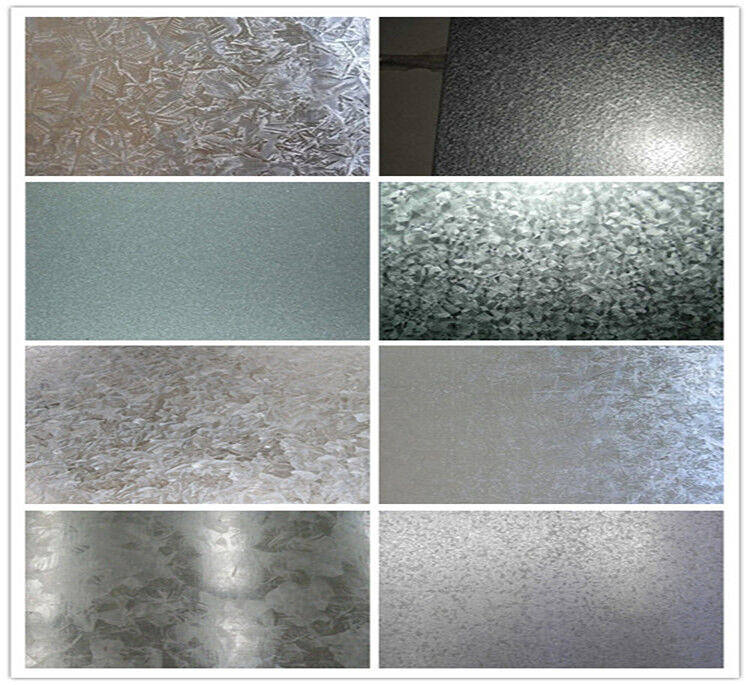

| Surface Structure | Mini/Big Spangle |

| Surface Treatment | Anti-Finger printing ,Chromated, oiled/ non-oiled |

| Package | standard export package (Detailed picture is as follows)Standard Ocean Freight PackageInside: Anti-rust paper,Plastic.Outside: Steel inner and outside guard board,Circle Iron guard board for both side,Outside iron guard board, 3 Radial Strapping and 3 Latitude Strapping.We can also pack according to your requirement. |

| Hardness | soft (normal), hard, full hard(G300-G550) |

| HS code | 721049 |

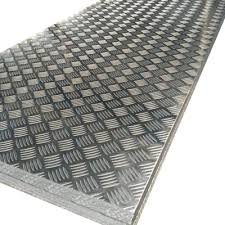

| Application | Hot dip galvanized steel is widely used in light industry, household applicances, automotive and construction industry. For various types of industrial and civil construction industry, light steel keel, building level board, corrugated board, roller shutter doors. |

| Brand name | Wisdom STEEL |

| Country of origin | China |

| Business type | Supplier and manufacturer |

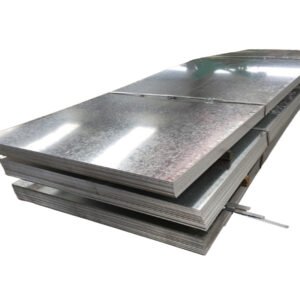

| Product Name | Galvanized Sheet |

| Material | ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345SGCH/DX51D+Z,DX52D+Z,DX53D+Z,DX54D+Z,S220GD+Z/A653 |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Grade | |

| Width | 600-1500mm or as required |

| Thickness | 0.12-4.0mm or as required |

| Length | As customer’s requirement |

| Surface Structure | Regular spangle, Minimal Spangle, Zero Spangle, Big Spangle |

| Surface Treatment | Oiled and chromated, Anti fingerprints |

| Zinc Coating(g/m2) | 30-275g/m2 |

| Coil Diameter | 508mm/610mm |

| Coil Weight | 3-5 Tons or as required |

| Certification | ISO , SGS , BV |

| Technique | Cold Rolled / Hot Rolled |

| Edge | Mill Edge/ Silt Edge |

| Quality | Mill Test Certificate supplied with the shipment ,third party inspection is acceptable |

| Application | |

| Package | Standard Ocean Freight PackageInside: Anti-rust paper,Plastic.Outside: Steel inner and outside guard board,Circle Iron guard board for both side,Outside iron guard board, 3 Radial Strapping and 3 Latitude Strapping.We can also pack according to your requirement. |

| Delivery Time | 3~15days,according to the order’s quantity |

| MOQ | 5 Tons |

| Payment term | 30%T/T Advance + 70% Balance |

Available Size

| Thickness (mm) | Mill Edge Width (mm) |

Cut Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Coil | 1.50~6.50 | 720~1860 | 762 | |

| Coil | 6.51~10.00 | 850~1500 | 762 | |

| Strip | 1.50~6.50 | 30~720 | 762 |

| Thickness (mm) | Mill Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Plate | 6.00~150 | 500~4000 | 1200~18000 |

| Sheet | 1.50~5.99 | 50~1845 | 760~6100 |

Specifications and Parameters

| Metallic Chromium Layer (mg/m2) (one side) | Chromium Oxide Layer (mg/m2) (one side) | ||

|---|---|---|---|

| Minimum Average Coating Weight |

Maximum Average Coating Weight |

Minimum Average Coating Weight |

Maximum Average Coating Weight |

| 50 | 150 | 5 | 35 |

| Categorization | Category | Code (s) | |

|---|---|---|---|

| Black Plate | - | MR, L | |

| Temper Grade | Single Reduce | T-1.5, T-2, T-2.5, T-3, T-3.5, T-4, T-5 | |

| Double Reduce | DR-7M, DR-8, DR-8M, DR-9, DR-9M, DR-10 | ||

| Annealing | Continuous Annealing | CA | |

| Box Annealing | BA | ||

| Surface Finish | Single Reduce | Bright surface | B |

| Stone surface | R | ||

| Stone rough surface | R2 | ||

| Matte surface | M | ||

| Double Reduce | Stone surface | R | |

| Matte surface | M | ||

| Electrochemical passivation | CE | ||

| Edge Shape | Straight line | SL | |

| Temper Grade Code | Hardness (HR30Tm) | |

|---|---|---|

| Target | Permissible Range | |

| T-1.5 | 51 | 51±3 |

| T-2 | 53 | 53±3 |

| T-2.5 | 55 | 55±3 |

| T-3 | 57 | 57±3 |

| T-3.5 | 59 | 59±3 |

| T-4 | 61 | 61±3 |

| T-5 | 65 | 65±3 |

| DR-7M | 71 | 71±5 |

| DR-8/DR-8M | 73 | 73±5 |

| DR-9 | 76 | 76±5 |

| DR-9M | 77 | 77±5 |

| DR-10 | 80 | 80±5 |

| Hardness (a) is the average hardness of two test specimens, and one of the test values is allowed to exceed the specified permissible range by one unit. | ||

Application of TFS PLATE

| Applications of Tinplate and TFS |

| ETP is primarily used for packaging foodstuffs and beverages, but it is also used in containers for oils, grease, paints, polishes, chemicals and many other products. Aerosol containers and caps and closures are also made from ETP. |

| TFS are most frequently used for can tops, screw and lug caps, snap and press-on closures and shallow-drawn food cans |

TFS Product Quality Control Items

| Mechanical Properties | Hardness, yield strength, tensile strength |

| Dimensional Accuracy | Thickness, width, cut length |

| Plate Shape Parameters | Bowness (C warp, L warp), camber, askewness, edge waviness |

| Corrosion Resistance | Metallic chromium amount, chromium oxide amount |

| Paintability & Printability | Oil type, film thickness, passivation method, passivation process, passivation film thickness, smudge, surface stains |

Tin Plate TFS Tin Free Steel Tinplate Sheet for Can Cap Food Packing SPTE TFS |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Type of Steel

Surface finish

Typical Application

Note: Making cans with DR materials, please pay a special attention to the rolling direction. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||