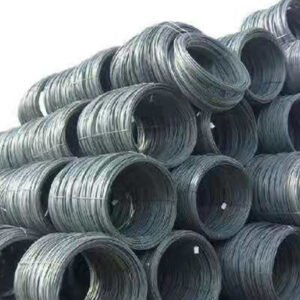

Q195 Q235 SAE1010 5.5mm 5.0mm 6mm 8mm Low Carbon Steel Wire SAE1006 SAE1008 82B SAE1008 galvanized STEEL WIRE ROD IN COILS FOR MAKING NAILS

Wire is available in both low carbon and high carbon quality steel. Low carbon wire is available as galvanized, bright, and annealed with wire processing options that include cold heading and straighten and cut. Used primarily for components in applications such as the construction, automotive and military. Carbon steel wire comes in diameters that range from 0.008” to 1.25” depending on the type. This type of carbon wire forms easily and can handle moderate flattening and bending.

|

Carbon Steel Wire

|

|

|

Product Name

|

SAE1006 1008 82B low carbon steel wire 5.5mm 5.0mm 6mm 8mm Hot Rolled Carbon Steel Wire Rod Coil PC steel wire rod for nail

|

|

Material

|

SAE1006-1080,WA1010,Q195,SWRH32-37,SWRH42A-77A,SWRH42B-82B

|

|

Size Tolerance

|

±1%

|

|

Wire Gauge

|

1 – 50 mm

|

|

Dia tolerance

|

+/-0.3mm

|

|

Process

|

Hot rolled, Cold Drawn

|

|

Length

|

As customer’s request

|

|

Technology

|

Hot roll, cold roll, cold drawn, ect.

|

|

Edge

|

Mill Edge Slit Edge

|

|

Certifications

|

MTC,ISO9001, BV,TUV

|

|

Payment

|

T/T,L/C,Western Union,Paypal,Apple Pay,Google Pay,D/A,D/P,MoneyGram

|

|

Price Term

|

Ex-work, FOB, CIF , CFR, etc

|

|

Delivery time

|

Usually 15 working days, your purchase volume determines our delivery time

|

|

Sample

|

Free,Contact us to learn more

|

|

Packing

|

Industry standard packaging or according to client’s requirement

|

High carbon wire is used in diverse applications across various industries. We offer bright wire, galvanized wire, and PC wire in diameters ranging from 0.011” to 0.312” and strand and rope with diameters from 1/8” to ½”. Our exceptional high carbon wire is found in quality musical instruments and fine furniture as well as in construction and industrial applications. This type of carbon steel wire is stronger due to the higher carbon content and less ductile than low carbon wire.

| carbon steel wire rod | |

| SAE1006 SAE1008 low carbon steel wire | |

| Product name: | SAE1006 SAE1008 low carbon steel wire |

| Place of Origin: | Shandong , China |

| Application: | Building Construction |

| Standard: | AiSi |

| Length: | 6m 12m |

| Grade: | HRB400/HRB500/ASTM/GR |

| Tolerance: | ±5% |

| Processing Service: | Bending, Welding, Decoiling, Cutting, Punching |

| Invoicing: | by actual weight |

| Delivery Time: | 8-14 days |

| Diameter: | 6mm-32mm |

| Technique: | Hot Rolled/Cold RolledSteel Rebar |

| Port: | Tianjin |

| Packaging Details | in bundles, in bulk, customized packing. |

Product Specification and Size :

Carbon Steel Wire Rod

Low and Middle Carbon Steel Wire Rod

High Carbon Steel Wire Rod

Cold Heading Carbon Steel Wire Rod

Free Cutting Steel Wire Rod

Alloy Steel Wire Rod

galvanized steel wire rod

welded carbon steel wire rod

SAE1008, SAE1018 and SAE1006 wire rods are low-carbon and highly versatile. this specification for hot-rolled steel wire rods for general engineering purposes. SAE stands for Society of Automotive Engineers. These are American standard steel grades designated by the SAE-AISI system. These wires are used in the manufacturing of nails, screws, wire mesh, wire ropes, and other wire-based items. They are known for their excellent surface finish, which makes them suitable for applications where appearance is essential. They offer excellent formability, drawability, and weldability and are widely used. These rods have excellent corrosion resistance and are highly durable. They are commonly treated using wire drawing processes to produce different wires.

Factors to consider when wire rod drawing to make fasteners

Material selection: the choice of material for the wire rods is crucial. Common materials include carbon steel and various alloys. Each material has different properties, such as strength, corrosion resistance, upsettability (a measure of the ductility) and cost, which should be considered based on the intended application.

carbon _steel_Coil_wire_rods

Wire diameter: the diameter of the wire rods determines the size of the nails or screws produced. It’s essential to select the appropriate diameter based on the desired strength and functionality of the fastener.

Wire quality: the quality of the wire rods directly affects the quality of the nails and screws. Factors such as tensile strength, surface finish, upsettability (a measure of the ductility) and uniformity of the wire should be considered to ensure consistent performance and durability.

Manufacturing process: various manufacturing processes can be used to fabricate nails and screws from wire rods like cold heading (a length of wire is inserted into a die and then struck with a punch at high speed and pressure), thread rolling (produces threads on cylindrical parts such as bolts, screws, etc.), and heat treatment. The choice of process depends on factors such as the fasteners’ desired shape, size, and properties.

Surface treatment: surface treatment, such as galvanising or coating, can enhance the corrosion resistance and appearance of the nails and screws. The appropriate surface treatment should be selected based on the environmental conditions and the intended use of the fasteners.

Quality control: rigorous quality control measures should be implemented throughout the fabrication process to ensure that the nails and screws meet the required specifications and standards. This includes monitoring dimensional accuracy, mechanical properties, and surface finish.

Key performance indicators

Tensile Strength measures the maximum stress a material can withstand while being stretched or pulled before breaking. For steel wire rods like SAE1008, SAE1018, and SAE1006, typical tensile strengths can vary based on processing, heat treatment, and alloying elements. However, these grades generally exhibit tensile strengths within a specific range. For example:

SAE1008: Typically has a tensile strength ranging from 340 MPa to 420 MPa.

SAE1018: Typically has a tensile strength ranging from 440 MPa to 540 MPa.

SAE1006: Typically has a tensile strength ranging from 290 MPa to 380 MPa.

Coils_of_steel_wire_rod_on_truck_trailer_at_industrial_zone._Truck_receive_steel_wire_rod_from_warehouse_container_unstuffing_area.

Durability refers to the ability of a material to withstand various environmental and mechanical stresses over time without degradation. Steel wire rods like SAE1008, SAE1018, and SAE1006 are known for their durability, making them suitable for various applications.

Fasteners manufactured from low-carbon wire rods play a pivotal role across diverse industries due to their fundamental importance in assembly and construction applications. The chemical composition of low-carbon steel wire rods provides excellent weldability, making it easy to connect through various welding techniques and robust joints. These components, like bolts, screws, nails, and rivets, serve as the backbone for joining materials in the automotive, aerospace, construction, manufacturing, and electronics sectors.

Approximate Comparative Table

| Product Name | UNS | AISI | JIS | DIN | AWS |

| Carbon Steel | G10060 / G10750 | 1006 / 1075 | SWRM6~SWRM22 | Ck10 / Ck60 | |

| SWRCH6A~ASRCH22A | |||||

| SWRH62A~SWRH72B | |||||

| Free Cutting Steel | G12144 | 12 L14 | SUM 24L | 9 S MnPb36 | |

| Welding Steel | SWRY 11 | ||||

| YGW 11 | |||||

| ER 70S-6 | |||||

| EM 12K | |||||

| Low Alloy Steel | CSC, C-CH 35ACR, C-CH 40ACR, 10B21, 10B33, 50BV30 | ||||

1. Hot rolled wire rod of ball bearing steel:

Ball BEARING steel, referred to as bearing steel, is used to manufacture all kinds of rolling bearing ring (bushing) and rolling body (ball) steel. Due to the particularity of its use, bearing steel is required to have high and uniform hardness and wear resistance, high elasticity and fatigue strength. Sufficient toughness and hardenability, at the same time in the atmospheric environment or lubricant has a certain corrosion resistance. Some special purpose rolling bearings also require high temperature resistance, corrosion resistance, non-magnetic, ultra-low temperature, high precision, long life and other properties. Therefore, the selection of bearing steel and steel quality requirements are stricter than the general steel. Bearing steel usually refers to high carbon chromium steel, in addition to carburizing bearing steel, high carbon chromium stainless bearing steel. Generally used for rolling ball bearing steel hot rolled wire rod has 5 steel.

Main APPLICATIONS: Hot rolled wire rod of ball bearing steel is mainly used to manufacture steel balls (steel balls) of bearings.

2 . stainless steel rod:

Stainless steel rod is hot rolled by a variety of stainless steel materials of different types of organization.

Main uses: Stainless steel rod is mainly used in the manufacture of stainless steel wire, stainless spring steel wire, stainless top forged steel wire and stainless steel wire for steel wire rope. According to the main industrial use to distinguish, stainless steel rod also has stainless steel and stainless acid-resistant steel rod.

3. Stainless steel wire rod for welding:

Welding stainless steel rod and general stainless steel rod in the chemical composition is different. In order to ensure its excellent welding performance, improve the weld quality, welding stainless steel wire rod in the composition of the significant characteristics are low carbon content, phosphorus, sulfur and other toxic impurities, nickel, chromium content is high.

Main Applications: Mainly used in the manufacture of electrode core and wire.

| Low Carbon Wire | High Carbon Wire |

| Galvanized WireFrom 0.008″ to 0.437″Commercial coatingClass I, III, and IVPVC coating | Bright WireFrom 0.011″ to 0.312″Upholstery spring wireBorder and Brace wireLacing wireZig Zag wireLead patented for garage door springHard drawn class I and IIFlat wireFrom 0.011″ to 0.312″Music spring wire |

| Bright WireFrom 0.008″ to 1.125″Bright BasicPlating qualityIndented wireFlat wire | Galvanized WireFrom 0.066″ to 0.187″ACSR Core wire, class A and BFrom 0.018″ to 0.065″Hard drawn Class I and IIFrom 0.018″ to 0.065″Music spring wire |

| Annealed WireFrom 0.008″ to 1.125″Bright annealedBlack annealedSphereroidize annealed | PC wireFrom 0.0120″ to 0.237″Smooth and Indented |

| Cold Heading QualityFrom 0.060″ to 1.125″DFAR )drawn from annealed rod)SAFS (Spheroidize Annealed at Final Size)SAIP (Sphereoidize Annealed In-Process)Hard Drawn Zinc Phosphate Coating | Strand and RopesFrom 1/8″ to 1/2″ACSR StrangeGuy WireOverhead ground wireMessenger wireSpecialty small diameter ropes |

| Straight and Cut WireFrom 0.080″ to 0.562″ From 0.095″ to 40GalvanizedPlating qualityIndustrial quality |

Steel wire rod steel grade and standard:

1). Low Carbon Wire Rod used for various kinds of steel wire, nails and wire entanglement.

: JIS G 3505 SWRM6-22, SAE1006-1022 , ASTM A510

2). Welding Wire Rod used for CO2 gas shielded arc welding wire, submerged arc welding wire and general electrodes : JIS G3503

SWRY11-21

3). High Carbon Steel Wire Rod used for Spring Wire, Wire Rope, PC Wire

: JIS G3506 SWRH27-82A/B, ASTM A510 Grade 1042-1086, EN 10016 Grade C42D2 – C88D2

4). Hot Rolled Stainless Steel Annealed and Pickled Wire Rod : 301, 302, 302HQ, 303, 304, 304L, 304H, 305, 309, 309S, 310, 310S,

314, 316, 316L, 316Ti, 317, 321, 430, 430L, 409CB

Used for Wires, Welding Wire, Cold Heading Wire, Weaving/brading/knitting Wires, Spring Wire, Roping Wire, Free Cutting Wire, Staple/Nail Wire.

Diameter of Carbon Steel Wire Rod : 5.5mm, 6mm, 6.5mm, 7mm, 8mm, 9mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm

Diameter of Stainless Steel Wire Rod : 5.5mm – 30mm

5). Chinese Wire Rod

Low Carbon Wire Rod

– Q195 : C: 0.06-0.12%, Si: 0.12-0.30%, Mn: 0.25-0.50%, P/S: Max. 0.04%, Yield Strength: max.390MPA, Elongation: min. 30%.

– Q235 for wire drawing: C: 0.12-0.20%, Si: 0.12-0.30%, Mn: 0.30-0.60%, P/S: Max. 0.04%, Yield Strength: max.490MPA, Elongation: min.24%.

– Q235 for construction: C: 0.14-0.22%, Si: 0.12-0.30%, Mn: 0.30-0.65%, P/S: Max. 0.04%, Yield Strength: min.235MPA, Tensile: min.410MPA, Elongation: min. 23%.

High Carbon Wire Rod

– SWRH42A:C: 0.39-0.46%, Si: 0.15-0.35%, Mn: 0.30-0.60%, P/S: Max. 0.03%

– SWRH42B:C: 0.39-0.46%, Si: 0.15-0.35%, Mn: 0.60-0.90%, P/S: Max. 0.03%

– SWRH47A:C: 0.44-0.51%, Si: 0.15-0.35%, Mn: 0.30-0.60%, P/S: Max. 0.03%

– SWRH62A:C: 0.59-0.66%, Si: 0.15-0.35%, Mn: 0.30-0.60%, P/S: Max. 0.03%

– SWRH62B:C: 0.59-0.66%, Si: 0.15-0.35%, Mn: 0.60-0.90%, P/S: Max. 0.03%

– SWRH67A C: 0.64-0.71% ,Si: 0.15-0.35% ,Mn: 0.30-0.60% ,P/S: max. 0.03% (for bed springs)

– SWRH82A:C: 0.79-0.86%, Si: 0.15-0.35%, Mn: 0.30-0.60%, P/S: Max. 0.03%.

Application

Carbon steel wire rod is extensively used to manufacture many wire products, such as:

– Agricultural and commercial uses

– Bright wire for electrolytic zinc coating

– Normal for automatic nailing

– Barbed wire

– Chains

– Screws, nuts and bolts