EN AW 1050A H14 2011 2014A 2024 5083 5251 6026 6061 6063 T5 6082 7075 Aluminum alloy steel sheet plate for construction

Product description

Aluminum plate is a kind of rectangular plate processed by aluminum ingot. It can be used in a wide range of applications, including lighting, household appliances and furniture in daily life, as well as indoor decoration and decoration. In the industrial field, it can also be used in the processing of mechanical parts and the production of molds.

Classification of aluminum plates

Aluminum plate according to the amount of aluminum can be divided into pure aluminum plate, aluminum alloy aluminum plate.

The aluminum content of pure aluminum plate can reach 99 percent, which is the most aluminum content in aluminum plate. Moreover, pure aluminum plate does not contain other elements, and the price is cheaper compared with other types of aluminum plate.

Aluminum alloy aluminum plate is mainly composed of alloy elements, the aluminum content is far less than pure aluminum plate, but it has some special properties, can be used in special environments, such as aerospace equipment or ships.

Aluminum plate can be divided into thin aluminum plate, conventional aluminum plate, medium thick aluminum plate and thick aluminum plate according to its thickness.

The thickness of aluminum plate is the type of aluminum plate. The thickness of the thin aluminum plate is 0.15-2.0 mm; The thickness of conventional aluminum plate is between 20.-6.0 mm; The thickness of the medium thickness aluminum plate is between 6.0 and 25.0 mm; The thickness of thick aluminum plate is between 25 and 200 mm; Aluminum plates above 200 mm are considered super thick.

| Product Name | 1000 Series ,2000 Series , 3000 series, 5000 series , 6000 series, 7000 series Aluminum alloy steel plate and aluminum checkered steel plate sheet | |

| Thickness | 1.0mm-20.0mm | |

| Application Field | Mainly used in aircraft structure (such as skin, etc.), aerospace, weapons, engines,Piston, automobile body, ship hull and stress components, etc. | |

| Specification | Alloy | 1145, 3003, 3004, 3105, 5005, 5052 & 5251. 2017、2024、2A12 6063 6065 |

| State | O、T3、T351、T361、T4、T6、T81 T5 | |

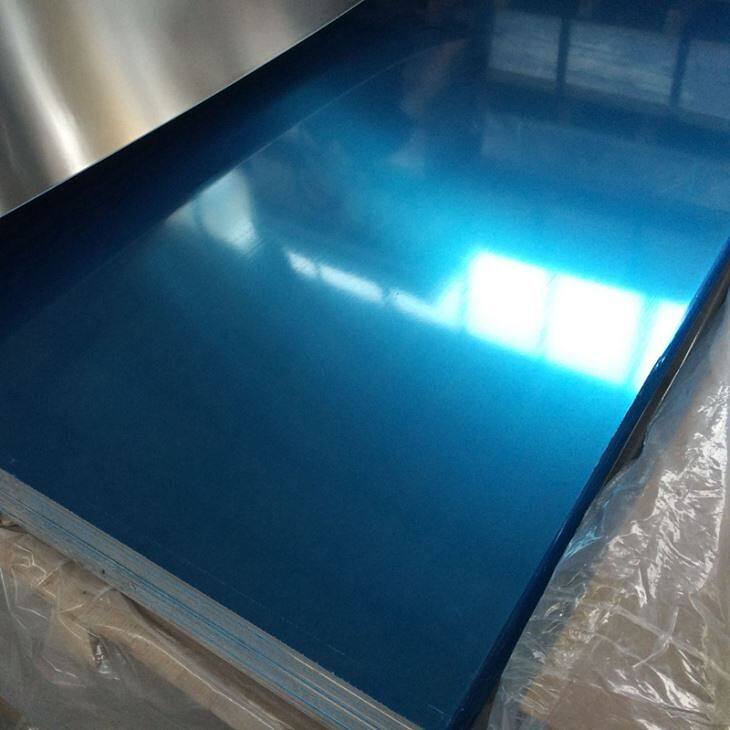

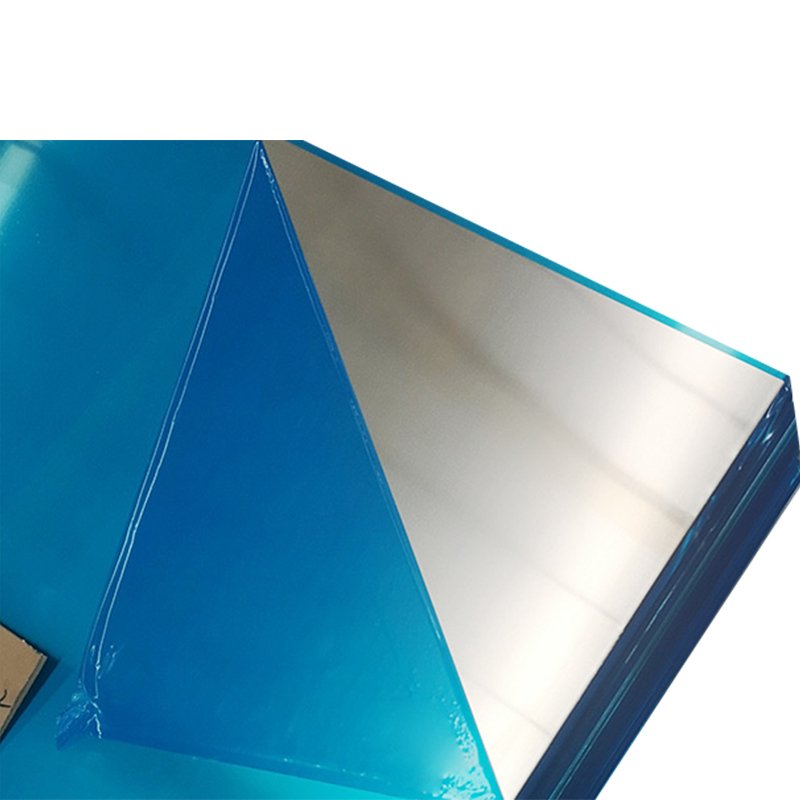

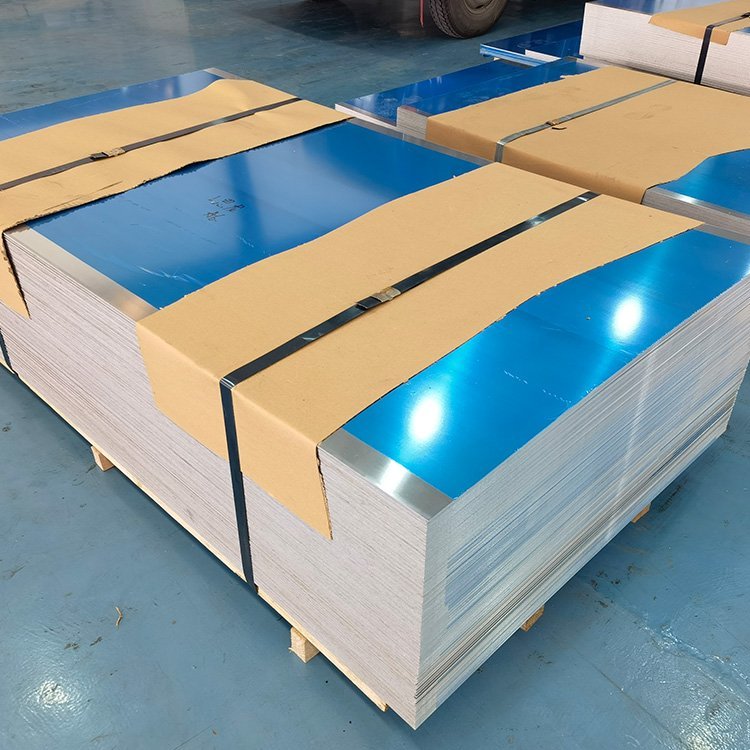

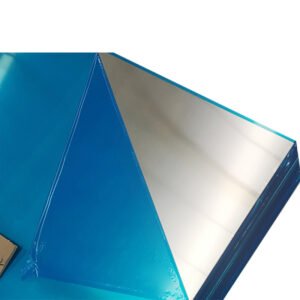

| Film type | Blue film, electrostatic blue film transparent film, black and white film, laser film, paper clip, stamping film, stretch film | |

| Product Details | 2017 | The 2017 aluminum plate is a typical duralumin in al-Cu-Mg system, with good comprehensive performance and the largest amount of duralumin. |

| 2024 | Also known as duralumin, the main alloying element is copper. Has high strength and good cutting performance, has a certain heat resistance, heat treatment, the disadvantage is poor corrosion resistance | |

| 2A12 | 2A12 aluminum plate products belong to high strength duralumin, which can be strengthened by heat treatment and has good weldability by spot welding. | |

| Product Usage | 2017 | Aluminum plate is usually used in rivets, general machinery parts, aircraft, ships, transportation, building structural parts, transport vehicle structural parts, propeller components and accessories, etc. |

| 2024 | Mainly used in aircraft structure (such as skin, etc.), aerospace, weapons, engines, pistons, automobile body, ship hull and stress components, etc. | |

| 2A12 | 2A12 aluminum plate is mainly used for machine exterior parts structure (skin, skeleton, rib beam, frame, etc.), wings, molds, military, transportation vehicles, compressors, rivets, missile components, truck wheels, spiral pulp components and other various structural parts. | |

Comparison of Alloy Designations for Aluminum Products

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 5xxx Series | 5052 | 5052 | EN AW-5052 |

| 5083 | 5083 | EN AW-5083 | |

| 5754 | – | EN AW 5754 | |

| 6xxx Series | 6005 | 6005 | – |

| 6060 | 6060 | EN AW-6060 | |

| 6061 | 6061 | EN AW-6061 | |

| 6063 | 6063 | EN AW-6063 | |

| 6082 | 6082 | EN AW-6082 | |

| 6463 | 6463 | – |

Chemical Composition

| Alloy | %Si | %Mg | %Mn | %Cu | %Fe | %Cr | %Zn | %Ti | %Others | %Al |

| EN AW-1050 A | 0.25Max | 0.05Max | 0.05Max | 0.05Max | 0.40Max | – | 0.07Max | 0.05Max | – | 99.5 Min |

| EN AW-1070 A | 0.20Max | 0.03Max | 0.03Max | 0.03Max | 0.25Max | – | 0.07Max | 0.03Max | – | 99.7 Min |

| EN AW-1100 | Si+Fe 0.95 Max | – | 0.05 Max | 0.05 – 0.20 | – | – | 0.10 Max | 0.05 Max | – | 99.0 Min |

| EN AW-2011 | 0.40 Max | – | – | 5.00 – 6.00 | 0.70 Max | – | 0.30 Max | – | Bi : 0.20– 0.60Pb : 0.20 – 0.60 | Remainder |

| EN AW-2014 | 0.50 – 1.20 | 0.20 – 0.80 | 0.40 – 1.20 | 3.90 – 5.00 | 0.70 Max | 0.10 Max | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-2024 | 0.50 Max | 1.20 -1.80 | 0.30 – 0.90 | 3.80 – 4.90 | 0.50 Max | 0.10 Max | 0.25 Max | 0.15 Max | 0.15 Max | Remainder |

| EN AW-3003 | 0.60 Max | – | 1.00 – 1.50 | 0.05 – 0.20 | 0.70 Max | – | 0.10 Max | – | 0.15 Max | Remainder |

| EN AW-3103 | 0.50 Max | 0.30 Max | 0.90 – 1.50 | 0.10 Max | 0.70 Max | 0.10 Max | 0.20 Max | 0.10 Max | – | Remainder |

| EN AW-6101A | 0.30 – 0.7 | 0.40 – 0.90 | 0.03 Max | 0.05 Max | 0.40 Max | – | – | – | 0.10 Max | Remainder |

| EN AW-6005 | 0.60 – 0.90 | 0.40 – 0.60 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6351 | 0.70 – 1.30 | 0.40 – 0.80 | 0.40 – 0.80 | 0.10 Max | 0.50 Max | – | 0.20 Max | 0.20 Max | 0.15 Max | Remainder |

| EN AW-6060 | 0.30 – 0.60 | 0.35 – 0.60 | 0.10 Max | 0.10 Max | 0.10 – 0.30 | 0.05 Max | 0.15 Max | 0.10 Max | – | Remainder |

| EN AW-6061 | 0.40 – 0.80 | 0.80 – 1.20 | 0.15 Max | 0.15 – 0.40 | 0.70 Max | 0.04 – 0.35 | 0.25 Max | 0.15 Max | – | Remainder |

| EN AW-6063 | 0.20 – 0.60 | 0.45 – 0.90 | 0.10 Max | 0.10 Max | 0.35 Max | 0.10 Max | 0.10 Max | 0.10 Max | – | Remainder |

| EN AW-6082 | 0.70 – 1.30 | 0.60 -1.20 | 0.40 – 1.00 | 0.10 Max | 0.50 Max | 0.25 Max | 0.20 Max | 0.10 Max | – |

Mechanical Properties

| ALUMINUMALLOY | Grade | NormalTemper | Temper | Tensile StrengthN/mm² | Yield StrengthN/mm² | Elongation% | Brinell HardnessHB | |

| Plate | Bar | |||||||

| 1XXX | 1050 | O,H112,H | O | 78 | 34 | 40 | – | 20 |

| 1060 | O,H112,H | O | 70 | 30 | 43 | – | 19 | |

| Al-Cu(2XXX) | 2019 | O,T3,T4,T6,T8 | T851 | 450 | 350 | 10 | – | – |

| 2024 | O,T4 | T4 | 470 | 325 | 20 | 17 | 120 | |

| Al-Mn(3XXX) | 3003 | O,H112,H | O | 110 | 40 | 30 | 37 | 28 |

| 3004 | O,H112,H | O | 180 | 70 | 20 | 22 | 45 | |

| Al-Si (4XXX) | 4032 | O,T6,T62 | T6 | 380 | 315 | – | 9 | 120 |

| Al-Mg(5XXX) | 5052 | O,H112,H | H34 | 260 | 215 | 10 | 12 | 68 |

| 5083 | O,H112,H | O | 290 | 145 | – | 20 | – | |

| Al-Mg-Si(6XXX) | 6061 | O,T4,T6,T8 | T6 | 310 | 275 | 12 | 15 | 95 |

| 6063 | O,T1,T5,T6,T8 | T5 | 185 | 145 | 12 | – | 60 | |

| Al-Zn-Mg(7XXX) | 7003 | T5 | T5 | 315 | 255 | 15 | – | 85 |

| 7075 | O,T6 | T6 | 570 | 505 | 11 | 9 | ||

At present, various aluminum sheet profiles and building materials will be used in the construction process of many large shopping plazas and office buildings. Among them, alloy aluminum plate with its unique performance advantages, high strength, good corrosion resistance, by many customers and friends welcome. The alloy aluminum plate has high hardness, strong plasticity and strong bearing capacity. Therefore, it has been widely used. So, what are the main applications of alloy aluminum plate?

1. Application of alloy aluminum plate: ships.

The characteristics of ship production are that the materials used should have good performance, not easy to wear, not easy to corrosion, so the alloy aluminum plate is the material of choice. Because the alloy aluminum plate is mainly made of aluminum, good performance, not easy to damage, long service life, can meet the requirements of ship production.

2. Application of alloy aluminum plate: refrigerator.

Refrigerator production is characterized by good sealing performance. Refrigerator in the process of use, need to refrigerate and preserve the effect, so the use of materials can meet these two requirements, so the alloy aluminum plate is the choice. Because the sealing performance of alloy aluminum plate is very good, it can meet the production conditions of refrigerator.

3. Application field of alloy aluminum plate: mold.

There are many moulds, but in general, companies will choose aluminum to make moulds. Because aluminum has many advantages, low density, easy to move production, alloy aluminum plate is the material of die enterprises.

4. Application of alloy aluminum plate: aerospace equipment.

The materials used in space equipment must have good properties, not only in pressure or other aspects, but also must be able to work in harsh environments, so alloy aluminum plates are the choice. Because aluminum does not corrode easily, it can be of value even in harsh environments.

| Temper | Definition |

| O | Annealed |

| H14 | Strain Hardened, 1/2 Hard |

| H112 | Slightly strain harden from working at an elevated temperature or from limited amount of cold work |

| T4 | Solution heat-treated and naturally aged |

| T5 | Cooled from an elevated temperature shaping process and then artificially aged |

| T6 | Solution heat-treated and then artificially aged |

| T651 | Solution heat-treated, stress-relieved by stretching a controlled amount and then artificially aged |

| T66 | Solution heat-treated and then artificially aged – mechanical property level higher than T6 achieved through special control of the process (6000 series alloys) |

| T6511 | Solution heated-treaded, stress-relieved by stretching a controlled amount and then artificially aged. Minor straightening is allowed after stretching to comply with standard tolerances |

Comparison of Alloy Designations for Aluminum Products

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 5xxx Series | 5052 | 5052 | EN AW-5052 |

| 5083 | 5083 | EN AW-5083 | |

| 5754 | – | EN AW 5754 | |

| 6xxx Series | 6005 | 6005 | – |

| 6060 | 6060 | EN AW-6060 | |

| 6061 | 6061 | EN AW-6061 | |

| 6063 | 6063 | EN AW-6063 | |

| 6082 | 6082 | EN AW-6082 | |

| 6463 | 6463 | – |

5052 H32 1mm Alloy Aluminum plate

5086 Aluminum sheet plate

5086 aluminum plate is a high strength magnesium alloyed aluminum product primarily used in the marine industry due to its excellent corrosion resistance, especially to seawater. In addition to good corrosion resistance, this alloy also has good weldability characteristics.

6061 Aluminum sheet plate

6061 aluminum sheet is a magnesium and silicon alloyed aluminum material. This good all-purpose alloy has good corrosion resistance and formability and has medium strength. It has good machining characteristics and has excellent appearance after anodizing.

6063 Aluminum sheet plate

6063 aluminum sheet is made from a popular heat treatable magnesium/silicon alloy. This alloy has excellent corrosion resistance and weldability. Due to its finer grain structure, this is an excellent alloy choice for anodizing. Applications include air cylinder, electrical bus conductor and architectural.

5083 Aluminum sheet plate

This magnesium alloyed aluminum product is primarily used in the marine industry due to its excellent corrosion resistance, especially to seawater. In addition to good corrosion resistance, 5083 aluminum pipe also has good weldability characteristics for fabricating vessels.