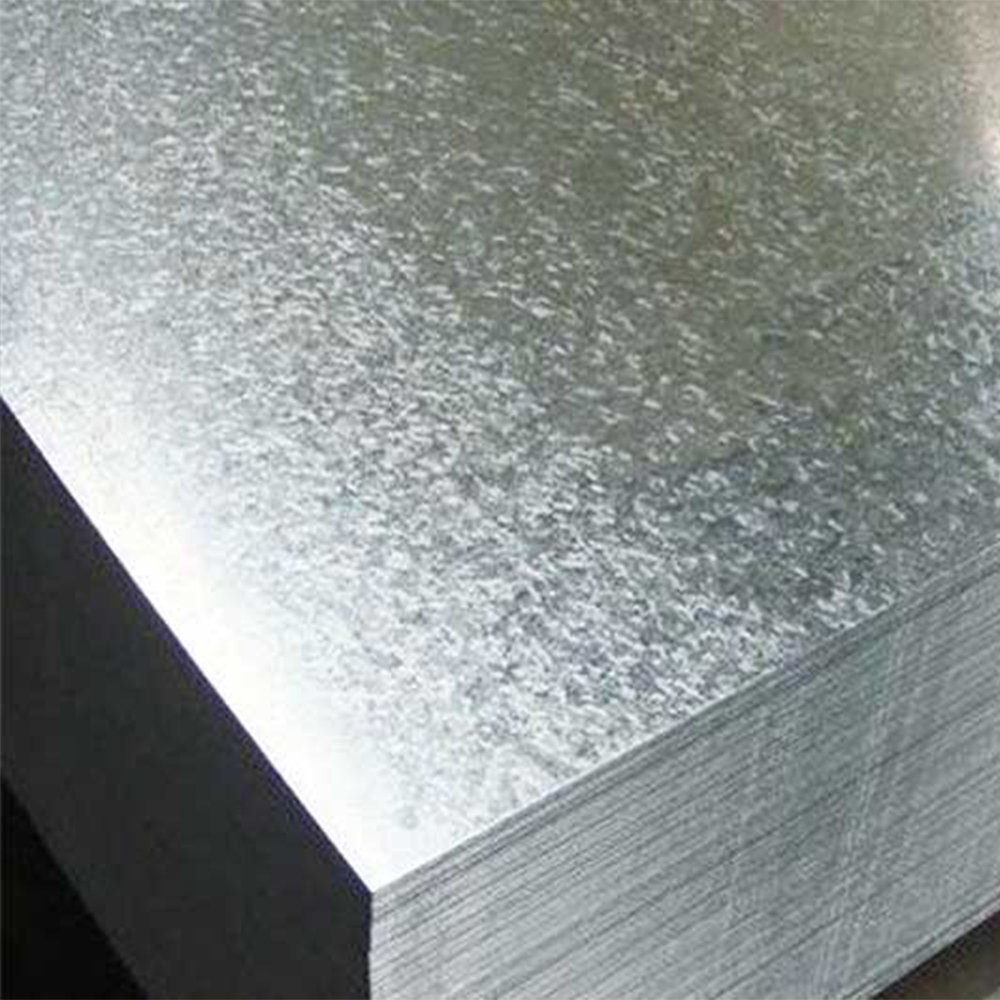

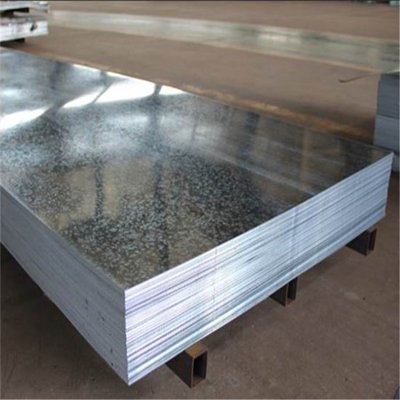

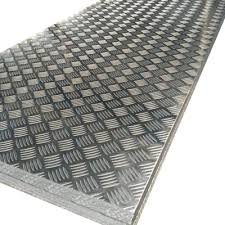

hot dip galvanized steel sheet . Hot-dip galvanized steel combines utility with beauty. It consists of tin, chrome, zinc or paint, which are the extra finish applied to the natural steel surface. The application of coating is to protect the surface of steel from oxidation and it is also used to enhance requirements for visual appearance.

Galvanized Steel sheet plate is specially designed steel sheets that are employed in several furbishing and manufacturing purposes. Steel coils are thin sheets that can be rolled up into incessant coils. The galvanized coils employed outdoor, as it shows anti rusting tendencies. Most significantly, it is used in constructing strong roofing system. Galvanized steel coil can be used outside because of its natural ability to avoid rust or corrosion. The coil itself is usually available in different dimensions. It may range from from 6 inches to 24 inches wide (15 cm to 51 cm), and up to 10 feet (3 m) long when rolled out flat.

Product Specification and Steel Grade (For Reference)

| Product name | hot rolled and cold rolled Galvanized Steel sheet plate |

| Material | ASTM A653, DX51D, Q195 ,DC01DX51D+Z, DX52D+Z , DX53D+Z ,DX54D+Z ,DX56D+ZHC1030 1300MS, HC1150 /1400MS, HC1200/1DC51D+Z , DC52D+Z, DC53D+Z, DC54D+Z ,DC56D+Z, H220PD+Z,H260PD+Z, H300LAD+Z,H340LAD+Z , H380LAD+ZSGCC CSTYPEB, SCGA2370D, SCG270E, SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+ZEN 10142,EN 10147,EN 10292,JIS G3302, ASTM A653/A653M, BQB 420 |

| Zinc Coating | 20-275g/m2 |

| Thickness | 0.13-200mm |

| Width | 100-4000 mm ,As customer’s requirement |

| length | 1000-12000mm ,As customer’s requirement |

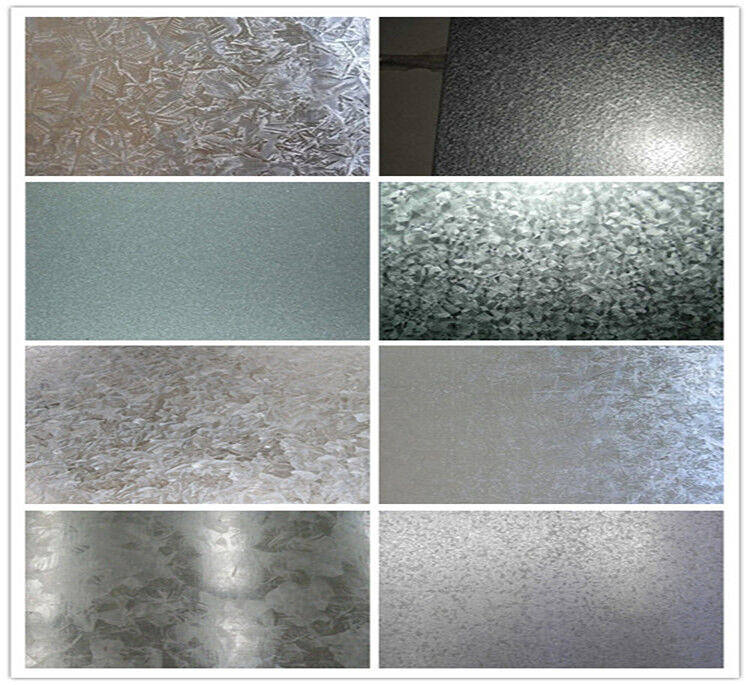

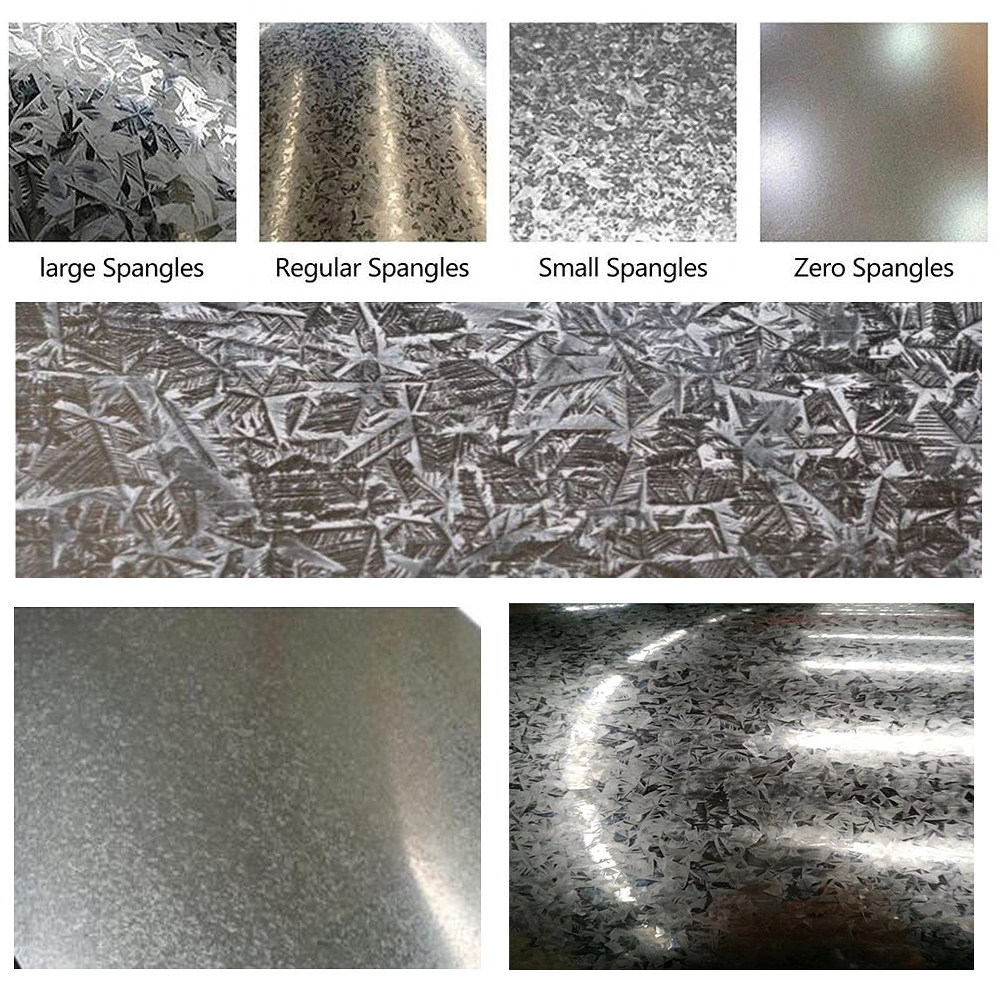

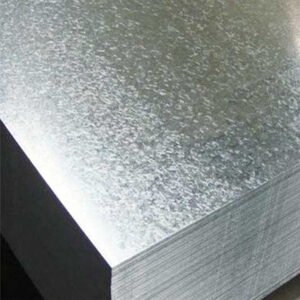

| Surface Structure | Mini/Big Spangle |

| Surface Treatment | Anti-Finger printing ,Chromated, oiled/ non-oiled |

| Package | standard export package (Detailed picture is as follows)Standard Ocean Freight PackageInside: Anti-rust paper,Plastic.Outside: Steel inner and outside guard board,Circle Iron guard board for both side,Outside iron guard board, 3 Radial Strapping and 3 Latitude Strapping.We can also pack according to your requirement. |

| Hardness | soft (normal), hard, full hard(G300-G550) |

| HS code | 721049 |

| Application | Hot dip galvanized steel is widely used in light industry, household applicances, automotive and construction industry. For various types of industrial and civil construction industry, light steel keel, building level board, corrugated board, roller shutter doors. |

| Brand name | Zhuosheng STEEL |

| Country of origin | China |

| Business type | Supplier and manufacturer |

| Product Name | Galvanized Sheet |

| Material | ASTM/AISI/SGCC/CGCC/TDC51DZM/TDC52DTS350GD/TS550GD/DX51D+Z Q195-q345SGCH/DX51D+Z,DX52D+Z,DX53D+Z,DX54D+Z,S220GD+Z/A653 |

| Standard | AISI,ASTM,BS,DIN,GB,JIS |

| Grade | |

| Width | 600-1500mm or as required |

| Thickness | 0.12-4.0mm or as required |

| Length | As customer’s requirement |

| Surface Structure | Regular spangle, Minimal Spangle, Zero Spangle, Big Spangle |

| Surface Treatment | Oiled and chromated, Anti fingerprints |

| Zinc Coating(g/m2) | 30-275g/m2 |

| Coil Diameter | 508mm/610mm |

| Coil Weight | 3-5 Tons or as required |

| Certification | ISO , SGS , BV |

| Technique | Cold Rolled / Hot Rolled |

| Edge | Mill Edge/ Silt Edge |

| Quality | Mill Test Certificate supplied with the shipment ,third party inspection is acceptable |

| Application | |

| Package | Standard Ocean Freight PackageInside: Anti-rust paper,Plastic.Outside: Steel inner and outside guard board,Circle Iron guard board for both side,Outside iron guard board, 3 Radial Strapping and 3 Latitude Strapping.We can also pack according to your requirement. |

| Delivery Time | 3~15days,according to the order’s quantity |

| MOQ | 5 Tons |

| Payment term | 30%T/T Advance + 70% Balance |

Available Size

| Thickness (mm) | Mill Edge Width (mm) |

Cut Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Coil | 1.50~6.50 | 720~1860 | 762 | |

| Coil | 6.51~10.00 | 850~1500 | 762 | |

| Strip | 1.50~6.50 | 30~720 | 762 |

| Thickness (mm) | Mill Edge Width (mm) |

Coil Inside Diameter (mm) |

|

| Plate | 6.00~150 | 500~4000 | 1200~18000 |

| Sheet | 1.50~5.99 | 50~1845 | 760~6100 |

Application

Application of galvanised steel coils

Galvanised steel coils are widely used in the following industries:

-

In the construction industry: to manufacture structural elements low-rise construction, light steel thin-walled structures, sandwich panels, lining of heat pipelines and various heat insulation, conditioning systems, metal roof shingle, profiled sheeting, culvert pipes, cladding of entry doors, elevators, reinforcement profiles for PVC windows and plastic doors, European-type fasteners for plasterboards, etc

-

In the automotive industry: to manufacture external and internal car body parts, as well as to repair external public transport body parts, eg for buses and trams)

-

In the machine building and instrumentation industries: to manufacture cases for electrical and mechanical equipment, home appliances, metering devices and packing

-

To manufacture houseware (tableware, bowls, buckets, tanks, baths, etc)

-

To manufacture colour-coated (and other type of coating) rolled steel

Hdg coil classification, product range and properties

Standards applied in different countries to set the requirements for galvanized steel coils specify steel grade and size ranges for these products. Galvanised steel coils are classified based on the following features:

-

Application of coated steel (profiling, cold forming, manufacture of steel structures)

-

Chemical composition of coating material (pure zinc, zinc-iron/zinc-aluminium/aluminium-zinc/zinc-magnesium alloys, etc)

-

Thickness/weight of protective coating

HDG coils according to European astandards

Galvanised steel coils as per the European EN 10346 standards can be coated with zinc, zinc-iron alloy, zinc-aluminium alloy, aluminium-zinc alloy or aluminium-silicon alloy:

-

Zinc coating (Z) is achieved by dipping the prepared strip into a bath with molten alloy, containing at least 99% zinc. This is the most common and traditional way of protecting rolled steel from corrosion.

-

Zinc-iron coating (ZF) is formed by dipping a strip into a bath of molten zinc (at least 99% zinc) with further annealing to form a zinc-iron coating with an Fe content of 8-12%. Such coating is stronger than the traditional zinc coating and has better adhesion with substrate steel due to mutual diffusion between the iron and zinc in the surface layers. That is why this coating is less exposed to lamination or pitting under impact, mechanical stresses or deformation of treated products.

-

Zinc-aluminium coating (ZA) is applied to rolled steel by dipping it into a bath of zinc and about 5% aluminium with a minor content of mishmetal (mix of metals). Rolled steel with such coating has better formability and corrosion protection properties compared with zinc-coated steel.

-

Aluminium-zinc coating (AZ) is applied by dipping steel into a bath of molten metal consisting of 55% aluminium and 1.6% silicon (with the remaining being taken up by zinc). The combined action of these metals ensures the best corrosion protection compared with other coatings.

-

Aluminium-silicon coating (AS) is created by dipping steel into a bath of molten metal containing aluminium and 8-11% silicon. Galvanized steel coil with such coating is highly resistant to oxidation at high temperature (up to 650°C) and highly resistant to chemical corrosion.

Galvanised steel coils manufactured according to the EN 10346 and DSTU EN 10346 standards can be made from the following steels:

-

Low-carbon steel for cold forming (DX51D – DX57D). These products are classified based on suitability for cold forming: DX51D – bending and profiling quality; DX52D – drawing quality; DX53D – deep-drawing quality; DX54D – special deep-drawing quality; DX55D – special deep-drawing quality (only +AS); DX56D – extra deep drawing quality; DX57D – super deep drawing quality.

-

Steel for construction and framing (S220GD – S550GD). Rolled products are arranged in increasing yield stress (Rp0.2), which is indicated in the marking. Rolled products of S220GD – S550GD steel are mainly used in the manufacture of formed sections (Z-, C-, sigma-, U-shaped profiles, etc) for light-gauge steel structures.

-

Steel with high yield strength for cold forming (HX160YD, HX180YD, HX180BD, HX220YD, HX300LAD, etc). Such rolled products are arranged in increasing yield stress (Rp0.2), which is indicated in the marking. The marking also contains the following information: H – high-strength flat rolled products for cold forming; Х – as-rolled condition (hot-rolled or cold-rolled) is not defined; D – designed for hot-dip coating; B – heat-treated steel; Y – steel with higher formability; LA – low-alloy / micro-alloy steel.

-

Cold-formable multi-phase steel (HDT450F, HCT490X, HDT590X, HCT780X, HCT980X, HCT780T, HDT580X, etc). Rolled products are arranged in increasing minimum tensile strength (Rm0.2), which is indicated in the marking. The marking also contains the following information: H – high-strength flat-rolled products for cold forming; С – cold-rolled products; D – hot-rolled products; Т (nnn) – the minimum tensile strength in MPa. The last symbol: F – ferrite-bainite, Х – dual-phase; Т – TRIP, С – complex-phase; М – martensite.

Galvanised coils as per the EN 10346 standard can be coated with zinc, zinc-iron alloy, zinc-aluminium alloy, aluminium-zinc alloy or aluminium-silicon alloy. The coating weight is expressed as grams per square metre and characterises the weight of the coating deposited on the both strip surfaces. The coating type (Z, ZF, ZA, AZ, AS) and nominal weight are indicated in the coating designation. Depending on the type of protective layer, the minimum weight of coating on both surfaces of a galvanized product can be 100-600 g/m2 (average value for three spots).

| Coating designation | Minimum total coating weight for both surfaces, g/m2 | Theoretical recommended values of the coating thickness per unit of surface for single-spot tests, microns | Density,g/cm3 | ||

| Three-spot | Single-spot | Reference value | Interval | ||

| Z100 | 100 | 85 | 7 | 5-12 | 7.1 |

| Z140 | 140 | 120 | 10 | 7-15 | |

| Z200 | 200 | 170 | 14 | 10-20 | |

| Z225 | 225 | 195 | 16 | 11-22 | |

| Z275 | 275 | 235 | 20 | 15-27 | |

| Z350 | 350 | 300 | 25 | 19-33 | |

| Z450 | 450 | 385 | 32 | 24-42 | |

| Z600 | 600 | 510 | 42 | 32-55 | |