Low Carbon A36 Hot Rolled Channel S355 S235 A572 Grade 50 150×150 Standard Viga Channel Steel Galvanized Steel c Channel

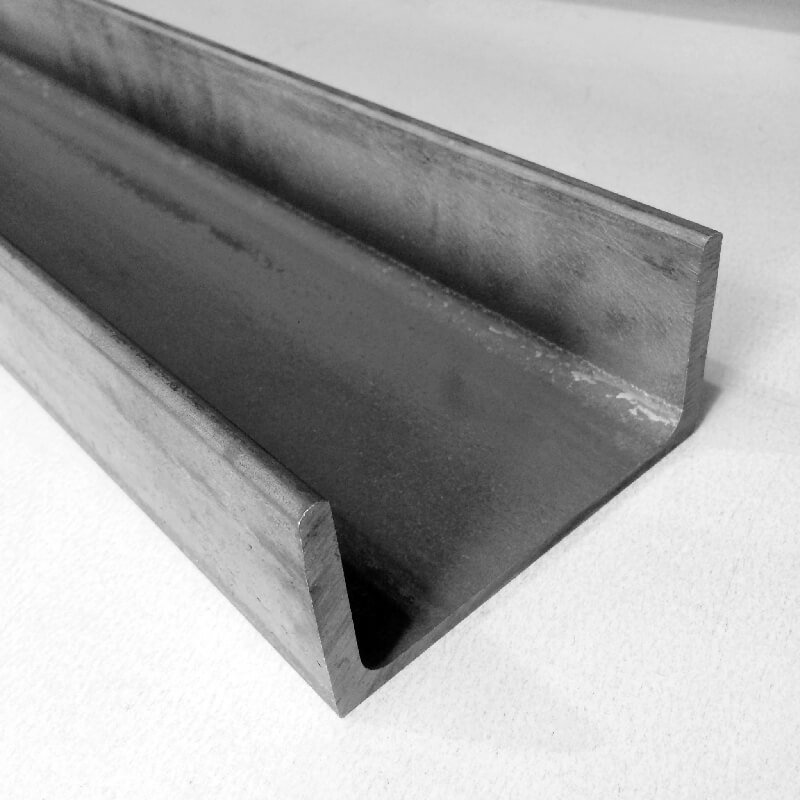

Channel steel is a long stripe of steel with a fluted section , construction and mechanical use of carbon structural steel, is a profile steel with complex section , its section shape is groove shape. Channel steel is a long stripe of steel with a fluted section , construction and mechanical use of carbon structural steel, is a profile steel with complex section , its section shape is groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing., Channel steel is often used together with I steel.

Channel steel is divided into ordinary u-steel and light Channel steel. The specification of hot rolled ordinary Channel steel is 5-40#. The specification of hot rolled flexible Channel steel is 6.5-30# after agreement between the purchaser and the supplier.

Channel steel according to the shape can be divided into four kinds :

cold bending equilateral u-steel, cold bending unequal side Channel steel, cold bending inner edge coil Channel steel, cold bending outer edge coil u-steel.

| Material | A36、St37、S235J0、S235J2,St52,16mn,S355JOQ195,Q215,Q235B,Q345B,S235JR,

S355JR,S355,SS440,SM400A,SM400BA572,GR50,GR60,SS540 |

| Dimensions | 50*37*4.5-400*104*14.575*40*3.8*7-152*76*6.4*9140*60*7*10-200*75*8.5*11.5 |

| Length | 6m, 9m, 12m or as customer requirement |

| Technology | Hot rolled , |

| Standard: | ASTM,AISI,JIS,GB, DIN,EN |

| Surface | Galvanized, paint;or as your request. |

| Supply ability | 2000Ton/day |

| Business type | Manufacturer |

| Certification: | ISO, SGS,BV ,CE |

| Application | widely used in building structure and engineering construction, such as room beam,ship beam, industrial furnace, etc. |

A36 hot rolled steel c channels, also referred to as “American Standard Channels”, are an excellent candidate for most processing techniques. A36 hot rolled steel channels have a rough, blue-grey finish. A36 material is a low carbon steel mild steel which is long lasting and durable. Hot rolled C channels have a “structural shape” meaning at least one dimension (excluding length) is greater than 3 inches. C channels inside flange surface have approximately a 16-2/3% slope, which distinguishes them from “MC” channels. Common applications include structural support, trailers, and other architectural uses. ASTM A36 / A36M-08 is the standard specification for carbon structural steel.

| American Standard Steel C Channel Sizes | |||||||||||||

| Desig- nation |

Area, A, in2 |

Depth, d, in |

Weight lb/ft |

Flange | Web Thickness tw, in |

Axis X-X | Axis Y-Y | x, in |

|||||

| Width, bf, in |

Thickness, tf, in |

I, in4 |

S, in3 |

r, in |

I, in4 |

S, in3 |

r, in |

||||||

| C15 x 50 | 14.7 | 15.00 | 50 | 3.716 | 0.650 | 0.716 | 404 | 53.8 | 5.24 | 11.0 | 3.78 | 0.867 | 0.798 |

| C15 x 40 | 11.8 | 15.00 | 40 | 3.520 | 0.650 | 0.520 | 349 | 46.5 | 5.44 | 9.23 | 3.37 | 0.886 | 0.777 |

| C15 x 33.9 | 9.96 | 15.00 | 33.9 | 3.400 | 0.650 | 0.400 | 315 | 42.0 | 5.62 | 8.13 | 3.11 | 0.904 | 0.787 |

| C12 x 30 | 8.82 | 12.00 | 30 | 3.170 | 0.501 | 0.510 | 162 | 27.0 | 4.29 | 5.14 | 2.06 | 0.763 | 0.674 |

| C12 x 25 | 7.35 | 12.00 | 25 | 3.047 | 0.501 | 0.387 | 144 | 24.1 | 4.43 | 4.47 | 1.88 | 0.780 | 0.674 |

| C12 x 20.7 | 6.09 | 12.00 | 20.7 | 2.942 | 0.501 | 0.282 | 129 | 21.5 | 4.61 | 3.88 | 1.73 | 0.799 | 0.698 |

| C10 x 30 | 8.82 | 10.00 | 30 | 3.033 | 0.436 | 0.673 | 103 | 20.7 | 3.42 | 3.94 | 1.65 | 0.669 | 0.649 |

| C10 x 25 | 7.35 | 10.00 | 25 | 2.886 | 0.436 | 0.526 | 91.2 | 18.2 | 3.52 | 3.36 | 1.48 | 0.676 | 0.617 |

| C10 x 20 | 5.88 | 10.00 | 20 | 2.739 | 0.436 | 0.379 | 78.9 | 15.8 | 3.66 | 2.81 | 1.32 | 0.692 | 0.606 |

| C10 x 15.3 | 4.49 | 10.00 | 15.3 | 2.600 | 0.436 | 0.240 | 67.4 | 13.5 | 3.87 | 2.28 | 1.16 | 0.713 | 0.634 |

| C9 x 20 | 5.88 | 9.00 | 20 | 2.648 | 0.413 | 0.448 | 60.9 | 13.5 | 3.22 | 2.42 | 1.17 | 0.642 | 0.583 |

| C9 x 15 | 4.41 | 9.00 | 15 | 2.485 | 0.413 | 0.285 | 51.0 | 11.3 | 3.40 | 1.93 | 1.01 | 0.661 | 0.586 |

| C9 x 13.4 | 3.94 | 9.00 | 13.4 | 2.433 | 0.413 | 0.233 | 47.9 | 10.6 | 3.48 | 1.76 | 0.962 | 0.669 | 0.601 |

| Desig- nation |

Area, A, in2 |

Depth, d, in |

Weight lb/ft |

Flange | Web Thickness tw, in |

Axis X-X | Axis Y-Y | x, in |

|||||

| Width, bf, in |

Thickness, tf, in |

I, in4 |

S, in3 |

r, in |

I, in4 |

S, in3 |

r, in |

||||||

| C8 x 18.75 | 5.51 | 8.00 | 18.75 | 2.527 | 0.390 | 0.487 | 44.0 | 11.0 | 2.82 | 1.98 | 1.01 | 0.599 | 0.565 |

| C8 x 13.75 | 4.04 | 8.00 | 13.75 | 2.343 | 0.390 | 0.303 | 36.1 | 9.03 | 2.99 | 1.53 | 0.854 | 0.615 | 0.553 |

| C8 x 11.5 | 3.38 | 8.00 | 11.5 | 2.260 | 0.390 | 0.220 | 32.6 | 8.14 | 3.11 | 1.32 | 0.781 | 0.625 | 0.571 |

| C7 x 14.75 | 4.33 | 7.00 | 14.75 | 2.299 | 0.366 | 0.419 | 27.2 | 7.78 | 2.51 | 1.38 | 0.779 | 0.564 | 0.532 |

| C7 x 12.25 | 3.60 | 7.00 | 12.25 | 2.194 | 0.366 | 0.314 | 24.2 | 6.93 | 2.60 | 1.17 | 0.703 | 0.571 | 0.525 |

| C7 x 9.8 | 2.87 | 7.00 | 9.8 | 2.090 | 0.366 | 0.210 | 21.3 | 6.08 | 2.72 | 0.968 | 0.625 | 0.581 | 0.540 |

| C6 x 13 | 3.83 | 6.00 | 13 | 2.157 | 0.343 | 0.437 | 17.4 | 5.80 | 2.13 | 1.05 | 0.642 | 0.525 | 0.514 |

| C6 x 10.5 | 3.09 | 6.00 | 10.5 | 2.034 | 0.343 | 0.314 | 15.2 | 5.06 | 2.22 | 0.866 | 0.564 | 0.529 | 0.499 |

| C6 x 8.2 | 2.40 | 6.00 | 8.2 | 1.920 | 0.343 | 0.200 | 13.1 | 4.38 | 2.34 | 0.693 | 0.492 | 0.537 | 0.511 |

| C5 x 9 | 2.64 | 5.00 | 9 | 1.885 | 0.320 | 0.325 | 8.90 | 3.56 | 1.83 | 0.632 | 0.450 | 0.489 | 0.478 |

| C5 x 6.7 | 1.97 | 5.00 | 6.7 | 1.750 | 0.320 | 0.190 | 7.49 | 3.00 | 1.95 | 0.479 | 0.378 | 0.493 | 0.484 |

| C4 x 7.25 | 2.13 | 4.00 | 7.25 | 1.721 | 0.296 | 0.321 | 4.59 | 2.29 | 1.47 | 0.433 | 0.343 | 0.450 | 0.459 |

| C4 x 5.4 | 1.59 | 4.00 | 5.4 | 1.584 | 0.296 | 0.184 | 3.85 | 1.93 | 1.56 | 0.319 | 0.283 | 0.449 | 0.457 |

| C3 x 6 | 1.76 | 3.00 | 6 | 1.596 | 0.273 | 0.356 | 2.07 | 1.38 | 1.08 | 0.305 | 0.268 | 0.416 | 0.455 |

| C3 x 5 | 1.47 | 3.00 | 5 | 1.498 | 0.273 | 0.258 | 1.85 | 1.24 | 1.12 | 0.247 | 0.233 | 0.410 | 0.438 |

| C3 x 4.1 | 1.21 | 3.00 | 4.1 | 1.410 | 0.273 | 0.170 | 1.66 | 1.10 | 1.17 | 0.197 | 0.202 | 0.404 | 0.436 |

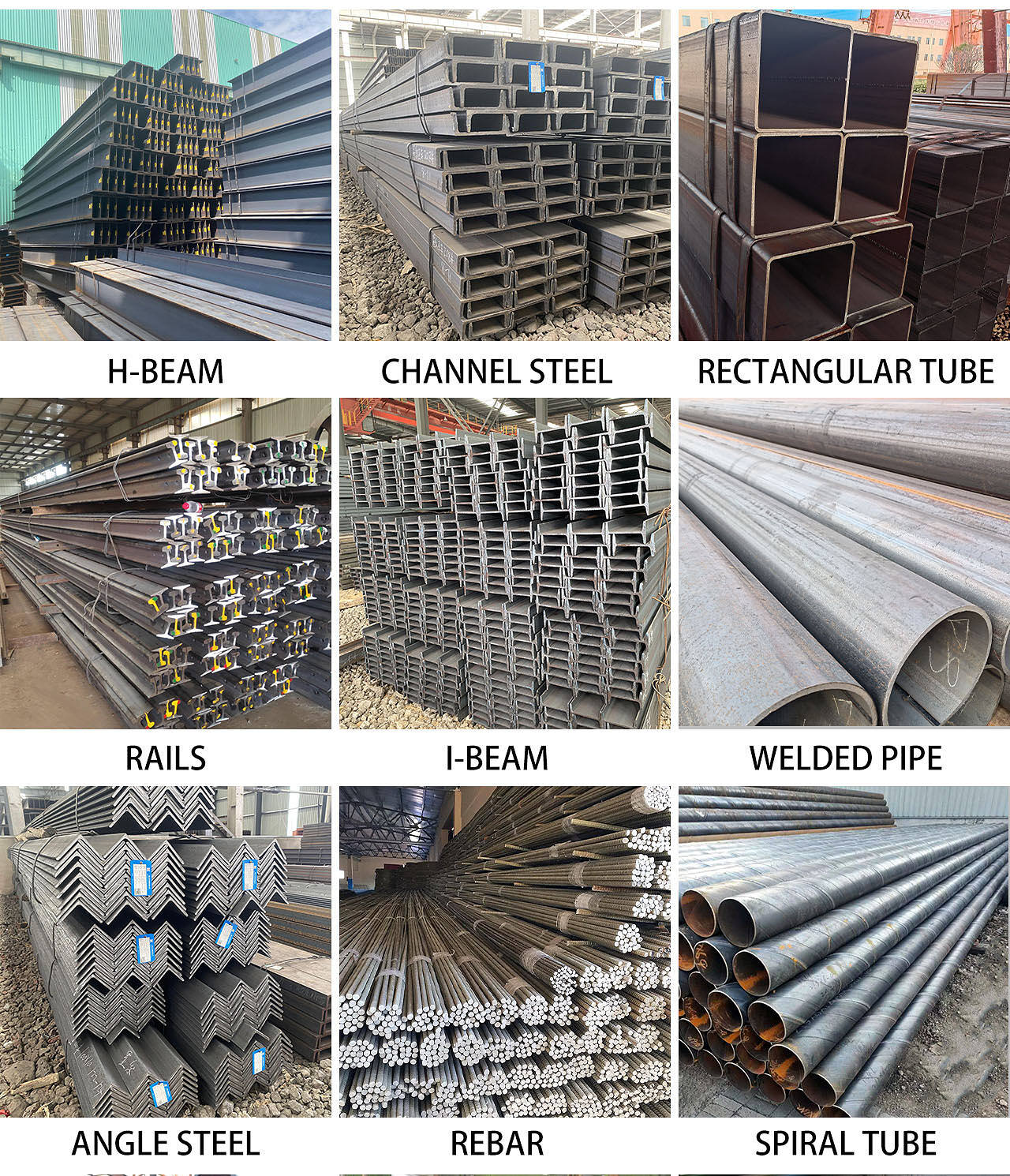

Steel channels and I beams are used to construct huge commercial, industrial, and residential buildings. Steel channels

are versatile and can be used as braces, joints, grids, studs, etc. Steel Channels are the main supporting component for metal

structures. They are welded or bolted in place.

Mild Steel C Channels

Information

Mild steel C channels, also known as mild steel channels or mild steel U channels, are hot-rolled carbon “C” shaped steel with inside radius corners that are widely used in general fabrication, manufacturing and structural applications. The C-shape or U-shape configuration of a mild steel channel provides superior strength and structural support when the load of a project is horizontal or vertical. The shape of a mild steel C channel also makes it easy to cut, weld, form and machine.

Applications

Uses of mild steel C channel include manufacturing, general fabrication, construction, transportation equipment, heavy machinery, industrial maintenance, agricultural implements, automotive industry and structural support applications.

Grades

Two of the most utilized grades of mild steel C channels are EN 10025 S275 and ASTM A36. EN 10025 S275 is a popular mild steel grade suitable for various use in engineering and general construction applications. Having low carbon steel specifications, EN 10025 S275 provides great machinability and high weldability, despite limited strength. Mild steel grade S275 is widely used in the construction, maintenance and manufacturing industries.

Mild steel grade ASTM A36 is another popular choice for carbon structural steels, which is mild and hot rolled. ASTM A36 has excellent welding properties and is suitable for different kinds of applications, including welding, bending and fabricating. Its flexibility and strength make ASTM A36 mild steel mostly used as base material for all construction and structural buildings. Depending on the thickness and corrosion resistance of the alloy, ASTM A36 mild steel is versatile with good formability and can be machined and formed using a variety of processes.

Types of Channels

-

Tapered Flange Channel (TFC): A channel with flanges that gradually taper from a wider base to a narrower top, optimizing strength while reducing weight.

-

Parallel Flange Channel (PFC): A channel where the flanges are parallel to each other, providing uniform strength and stability throughout its length.

-

UPN Channel (UNP European Standard): A channel with a U-shaped cross-section, commonly used in Europe for structural supports, providing high resistance to bending.

Common Grades, Sizes and Specifications

| Grades | Width | Height | Length | Thickness |

|---|---|---|---|---|

| ASTM A36 | Up to 100mm | Up to 380mm | From 1000mm to 12000mm | From 3.5mm |

| EN 10025 S275JR | Up to 100mm | Up to 380mm | From 1000mm to 12000mm | From 3.5mm |

| EN 10025 S355JR | Up to 100mm | Up to 380mm | From 1000mm to 12000mm | From 3.5mm |

| JIS G3101 SS400 | Up to 100mm | Up to 380mm | From 1000mm to 12000mm | From 3.5mm |

Other mild steel C channel sizes and grades are available upon request. You can request to cut your mild steel C channels down to size.