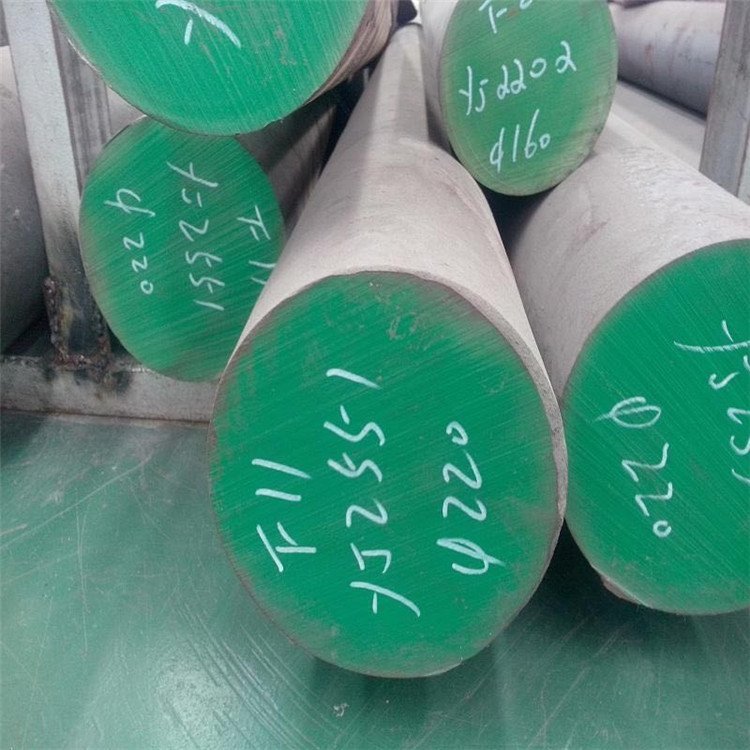

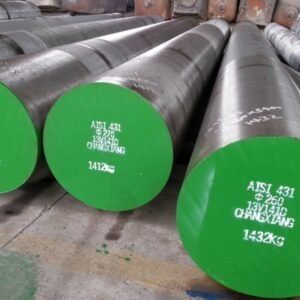

20CrMnTi(H) AISI 5120 Forged Round Bar ,SAE1045 C45 Hot Rolled Carbon Steel Round Bar Dia 50mm-200mm Cutting Steel Carbon Steel Rod Bar Carbon Steel Bright Bar rod ,

AISI 1045/1020/5140/4140/8620 ASTM A36/A572/A283 Carbon Steel Round Bar

Wisdom steel metal is a recognized manufacturer and exporter of CS Round Bars, which contain a small amount of incidental elements leftover from steelmaking. We also offer the same in different grades and specifications such as Carbon Steel Round Bars, Carbon Steel Round Bars, Carbon Steel Round Bars, Carbon Steel Round Bars, and EN SERIES Carbon Steel Round Bars.

To change the properties of Carbon Steel Square Bars is by adding alloying elements other than carbon that produce characteristics not achievable in plain carbon steel. Each of the approximately 20 elements used for Carbon Steel Flat Bars has a distinct influence on microstructure and on the temperature, holding time, and cooling rates at which microstructures change.

Wisdom steel metal is one of the pioneer stockiest and exporter for high-quality Carbon Steel Threaded Bars, which alter the transformation points between ferrite and austenite, modify solution and diffusion rates, and compete with other elements in forming intermetallic compounds such as carbides and nitrides. There is a huge amount of empirical information on how alloying in Carbon Steel Hollow Bars affects heat-treatment conditions, microstructures, and properties. In addition, there is a good theoretical understanding of principles, which, with the help of computers, enables engineers to predict the microstructures and properties of Carbon Steel Hexagonal Bars when alloying, hot-rolling, heat-treating, and cold-forming in any way.

Product Specification and Size

| Hot Rolled Round Bar | Cold Drawn Square Bar |

| Hot Rolled Square Bar | Cold Drawn Hexagon Bar |

| Cold Drawn Round Bar | Forged Bar |

Available Size

| Product Name | Diameter (mm) |

| Hot Rolled Round Bar | 25~600 |

| Hot Rolled Square Bar | 21~54 |

| Cold Drawn Round Bar | 6~101.6 |

| Cold Drawn Square Bar | 6~50.8 |

| Cold Drawn Hexagon Bar | 9.5~65 |

| Forged Bar | 200~1000 |

Sae 4130 4140 4150 4340 Alloy Carbon Steel Round Bar

Individual Steel Grades

1. SAE 4130 Steel

-

Properties: A popular chromium-molybdenum steel with medium carbon content. It offers a good balance of strength, toughness, and weldability. It is strong but less hardenable than higher-carbon grades.

-

Applications:

-

Aircraft engine mounts and structural tubing Automotive roll cages and chassis

-

Machine parts and jigs Pressure vessels

-

2. SAE 4140 Steel

-

Properties: A chromium-molybdenum steel with higher carbon than 4130. It is one of the most common alloy steels, known for its high strength, good fatigue resistance, and excellent wear resistance after heat treatment. It is tougher than 4150 but not as hard.

-

Applications:

-

Axles, shafts, and gears Bolts, nuts, and studs

-

Drill collars and tool holders High-strength machine components

-

3. SAE 4150 Steel

-

Properties: Similar to 4140 but with even higher carbon content. This results in superior hardenability, allowing it to achieve the highest hardness and wear resistance of the 41xx series. It is slightly less tough than 4140.

-

Applications:

-

Heavy-duty axles and drive shafts High-strength gears and sprockets

-

Military vehicle components Machine tools requiring extreme wear resistance

-

4. SAE 4340 Steel

-

Properties: A premium nickel-chromium-molybdenum steel. The addition of nickel gives it exceptional strength and toughness, even at very high strength levels. It has excellent deep hardenability, making it suitable for large, critical cross-sections.

-

Applications:

-

Aircraft landing gear and crankshafts High-strength bolts for critical applications

-

Heavy-duty gears, pinions, and sprockets Press rams and extrusion rams

-

Carbon Steel Bright Bar, Carbon Steel Round Bars, Carbon Steel Rods Suppliers and Dealer in China.

Carbon Steel Forged Bars Exporter, Carbon Steel Square Bar, Mild Steel Round Bar Specification, Carbon Steel Round Bar Specifications, Carbon Steel Round Bar, Suppliers of Carbon Steel Hex Bar, Carbon Steel Round Bars Manufacturer in China.

Simple Comparison

-

Carbon Content & Hardenability: 4150 > 4140 > 4130. For 4340, its hardenability is superior to all 41xx grades due to Nickel.

-

Toughness (at similar strength): 4340 > 4130 > 4140 > 4150

-

Cost: 4340 (most expensive) > 4150 ≈ 4140 > 4130

1. Breakdown by Steel Grade

These grades are defined by SAE (Society of Automotive Engineers) or AISI standards.

Carbon Steels (Good strength, wear resistance, and machinability)

-

SAE 1045 / C45: A medium-carbon steel. This is the workhorse of the list. It offers a good balance of strength, toughness, and machinability. It can be hardened by heat treatment (quenching and tempering) and is commonly used for shafts, gears, bolts, and other high-strength components.

-

SAE 1020: A low-carbon steel. It is softer, more ductile, and easier to weld than 1045, but it cannot be effectively hardened through heat treatment. It’s used for general-purpose applications like fixtures, brackets, and non-critical structural parts.

Alloy Steels (Enhanced properties through added elements like Chromium, Molybdenum, and Nickel)

-

SAE 4140 / AISI 4140 (Chromium-Molybdenum Steel): One of the most versatile and widely used alloy steels. The addition of Chromium and Molybdenum gives it excellent strength, toughness, and fatigue resistance. It responds very well to heat treatment and is used for high-stress components like axles, crankshafts, bolts, and drilling equipment.

-

SAE 4130 (Chromium-Molybdenum Steel): Similar to 4140 but with slightly lower carbon and chromium content. It has excellent weldability while maintaining good strength. Very popular in structural tubing for aerospace (airframe frames) and race car chassis, as well as for machined components.

-

SAE 4340 (Nickel-Chromium-Molybdenum Steel): A high-strength, high-toughness alloy steel. The addition of Nickel gives it superior impact resistance and the ability to be heat-treated to very high strength levels while maintaining ductility. Used for highly stressed parts like aircraft landing gear, heavy-duty axles, and high-strength bolts.

-

SAE 5140 (Chromium Steel): Similar to 4140 but without Molybdenum. It offers good hardenability and wear resistance, often used for gears, shafts, and machine parts.

-

SAE 8620 (Nickel-Chromium-Molybdenum Steel): A case-hardening or carburizing steel. It has a low-carbon core that remains tough and ductile, while the surface can be hardened to resist wear and fatigue. It is the standard choice for gears, pinions, and bearing components.

-

SAE 4150: A higher carbon version of 4130/4140, offering even higher strength and wear resistance after heat treatment, used for very high-stress applications.

2. Product Form & Processing

-

Hot Rolled: The steel is shaped at high temperatures. This leaves a rough, bluish-gray oxide layer (mill scale) on the surface. It is the most common and economical form.

-

Bright Bar / Bright Drawn: A Cold Finished product. Hot-rolled bars are pickled to remove scale and then cold-drawn through a die. This process:

-

Improves surface finish (smooth and bright).

-

Provides tighter dimensional tolerances.

-

Increases strength slightly through work hardening.

-

Is more expensive than hot-rolled.

-

3. Key Specifications

-

Form: Round Bar (also called Rod or Bar)

-

Diameter Range: 50mm – 200mm (This is a range for heavy-duty industrial components, from 2 inches up to 8 inches).

-

Service: Cutting – The supplier will likely cut the bars to your specified length.

Typical Applications for These Steel Grades

-

Automotive & Transportation: Axle shafts, crankshafts (4140, 4340), gears (8620, 4140), steering components, spindles.

-

Aerospace: Landing gear components (4340), airframe parts (4130 tubing), engine mounts.

-

Machinery & Equipment: Hydraulic piston rods, shafts, bolts, connecting rods, drill collars, dies, and tool holders.

-

Oil & Gas: Valve components, drilling tool joints, and high-strength fasteners.

-

General Manufacturing: Any high-strength, wear-resistant component that will be machined and heat-treated.

How to Choose the Right Grade

-

Required Strength & Heat Treatment:

-

For general machining and strength without heat treat: 1045 or 1020.

-

For parts to be through-hardened (quenched & tempered): 1045, 4140, 4340.

-

For parts requiring a hard, wear-resistant surface with a tough core (case hardening): 8620.

-

-

Weldability:

-

Easiest to Weld: 1020.

-

Good Weldability (with pre/post-heat): 4130.

-

Requires careful welding procedures: 4140, 4340.

-

-

Toughness & Impact Resistance:

-

For the highest impact and fatigue resistance: 4340 is superior.

-

For excellent all-around toughness: 4140.

-

-

Surface Finish & Dimensional Accuracy:

-

For general forging or rough machining: Hot-Rolled is sufficient.

-

For precision machining with a good finish: Specify Bright Bar.

-

In summary, this product listing is for a range of high-performance engineering steels used to create durable, load-bearing mechanical components. The choice depends entirely on the mechanical properties required for the final application, the manufacturing process (machining, welding, heat treatment), and the budget.