Basic Characteristics

1. Light weight: 10-14 kg/square meter, equivalent to 1/30 of the brick wall.

2. Heat insulation: core material thermal conductivity: 0.041 w/mk.

3. High strength: can be used as ceiling enclosure plate bearing, bending and compressive resistance; General houses do not use beams and columns.

4. Bright color: no surface decoration, color galvanized steel anticorrosion layer in 10-15 years.

5. Flexible and fast installation: the construction period can be shortened by more than 40%.

6. Oxygen index: (OI)32.0(provincial fire product quality inspection station).

Basic Info.

Product Description

Features and Performance

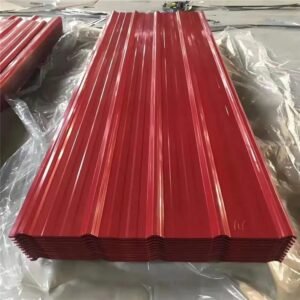

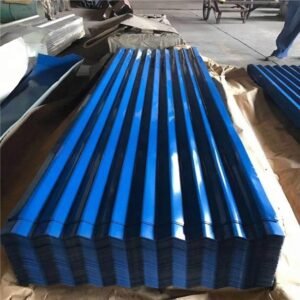

Color steel plate coating is a product made of cold rolled steel plate, galvanized steel plate, coated (roll coated) or composite organic film (PVC film, etc.) after chemical treatment on the surface, and then baked and cured. Some people also call this product “roller coated steel plate”, “plastic color steel plate”. Color plate products are rolled by manufacturers on continuous production lines, so they are also called color coated steel plate rolls. Color steel plate not only has high mechanical strength of iron and steel materials, easy to form the performance, but also good decorative coating materials and corrosion resistance. Color steel plate is a new material in today’s world. With the progress of science and technology, the enhancement of environmental awareness, the improvement of people’s living standards, color steel plate mobile housing more and more shows a strong vitality and broad market prospects, by the construction, home appliances, mechanical and electrical, transportation, interior decoration, office appliances and other industries of favor.

Product Description

Stainless Steel Coil / Strip

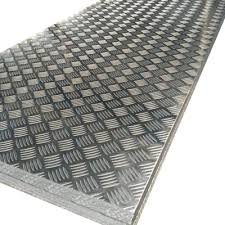

√ Precise cutting: using mature cutting technology, the edges are smooth and flat, without burrs

√ Strong versatility: aluminum replaces iron, aluminum replaces plastic, environmentally friendly regeneration, energy saving and emission reduction, not easy to corrode, not rusted

√ The surface is easy to handle: strong plasticity, light weight, rich surface treatment, can be stretched and bent, can be embossed and embossed

√ Due to the large number of product specifications, the display is incomplete, please contact us for detailed specifications, special specifications can be customized

| Product type | PPGI Color Coated galvanized Steel roof Sheet/Plate/Coil |

| Grade | 200/300/400Series–SS201,304,316.430 |

| Standard | JIS.AISI.ASTM.DIN.TUVBVSUS.etc |

| Thickness | 0.25-3.0mm |

| Width range | 30mm – 1500mm |

| Length | 2000/2438/3048mm customization |

| Color | Golden. black , sapphire blue. brown. rose gold. bronze. purple. gray.silver. champagne. violet. blue diamond or customization |

| Surface finish | NO.2B.BA.No.44K,6K,8K Hairline.CUSTOMIZED |

| Origin | POSCO.JISCO.TISCO.LISCOBAO STEEL etc. |

| Payment terms | 30%TT for deposit,70% balance before shipment or LC at sight |

| Lead time | 7 to 25 working days after the receipt of 30% deposit |

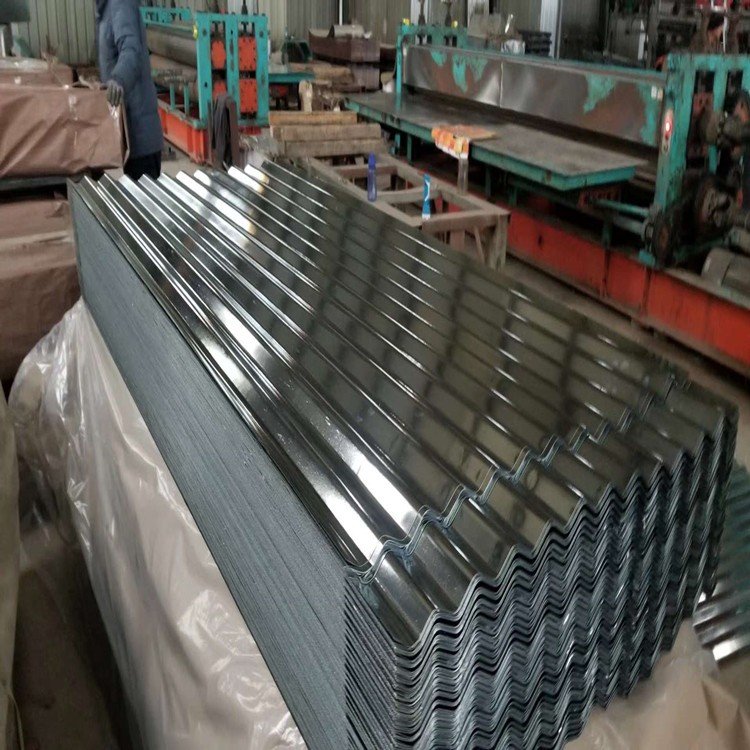

Different types of roofing sheets

Roofing sheets are manufactured from a range of materials, each known for their varying properties and applications on different types of roofs. Choosing the right roof sheet can increase the longevity and durability of your roof. Different types of roof sheets come with their own unique set of pros and cons. Each type caters to different needs. Your roof is only as strong as the materials that it comprises. The level of protection that your roof receives ultimately depends on the clever combination of various materials that work together to provide maximum performance. Whether the roof is for your garage, shed or a different building entirely, roofing sheets are vital for protecting your roof from harsh weather.

They act as a physical barrier, shielding the more vulnerable underlying components from high-winds, torrential downpours, snow and hail. Plus, thanks to various technological advancements, these sheets boast an incredible range of features and functions and are available in all manner of sizes. The only thing you need to know is which roofing sheet is best suited to the building you’re working on. There are different types of roofing sheets each with unique composition, advantages and applications, each of them are explained below.

The different types of roofing sheet

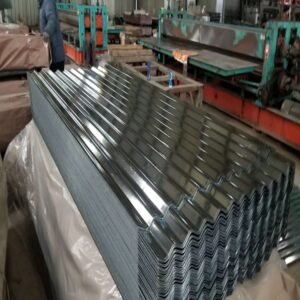

Corrugated roofing sheets

Corrugated roofing is highly durable and it is because of its shape. These sheets require the support strips to stabilize the material since the screws for fastening do go through the peak of the ribs. The curvature of the ribs and valleys prevents the screws from sealing adequately in the valleys. Because of the special corrugated shape, flimsy and lightweight metals like aluminum can also be equipped to undergo decades of weather beating. The most popular corrugated sheet is a galvanized steel sheet, which is used mostly as the base material. These roofing sheets are ideally used for protecting garages, porches and sheds.

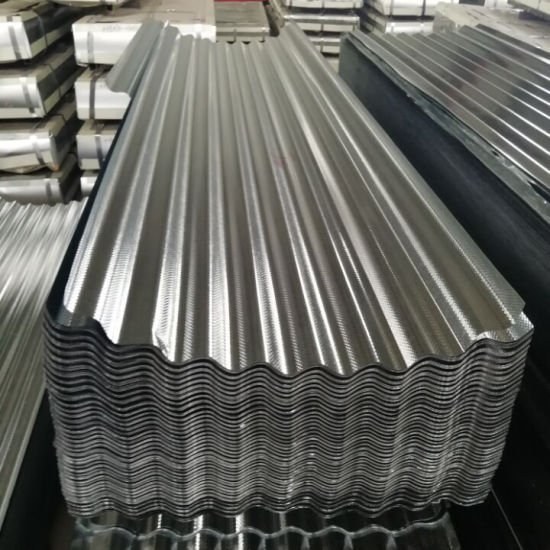

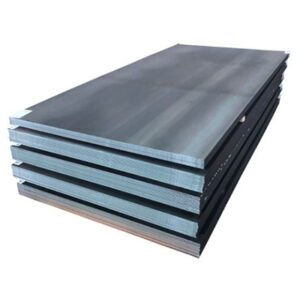

GI roofing sheets

The GI coating has a unique metallurgical structure and gives protection against any abrasion, or mechanical damage that may occur during transportation, erection and service. GI roofing sheets are fitting in providing automatic protection to any damaged area of the sheet. The sheets give them cathode or sacrificial protection to any small area damaged during transportation. Thus the entire length of the sheets is protected by the coating

Application:

- Disadvantages of Metal Roofing sheet: Zero Insulation. No protection from Heat or Cold. …

- Disadvantage: Leaks during Rains. …

- Disadvantage: Screw holes keep interiors dusty, always. …

- Alternatives to metal roofing sheets.

Color steel plate mobile room has the advantages of light weight, high strength, thermal insulation, beautiful and durable, is a senior building and decoration integrated installation fast. Color steel plate activity room construction clean, widely used in large-span workshop, warehouse, office building, villa, roof layer, air purification room, cold storage, shops, kiosks and temporary rooms. Light color steel plate sandwich board square meter weight less than 14KG can fully reduce the structural load, reduce the cost of the structure of the mobile room.