Hot Rolled Z Type Y390 Q390 Astm A36 Q345 Steel Sheet Pile SYW295 SYW390 SY295 SPIII U Type Hot Rolled Carbon Section Steel Piling Steel Sheet Pile

|

Product name |

400x100x10.5mm Type 2 Hot rolled U type steel sheet pile for construction | ||

| Materials | Q235,Q345,Q390 ,Q235 Q195 A36 A106 Q345,Q390 ,Y390 Q390 A36 Q345 SYW295 SYW390 SY295 | ||

| Technique | Hot rolled,cold formed | ||

| Type | U type Z type | ||

| Certificate | ISO 9001 ASTM BIS, AISI , | ||

| Length | Any length as customer’s request 6 meters 9 meters and 12 meters | ||

| Place of origin | China Mainland | ||

| Package | Bundle in bulk,seaworthy packing or as customer’s request | ||

| Application | flood project,construction project,bridge etc. | ||

| Brands | WISDOM | ||

| Payment term | TT IN ADVANCE, AND BALANCE BEFORE SHIPPING or LC at sight | ||

| Packing | Bulk vessel or container | ||

| Delivery | In 15 days after receipt of L/C or TT | ||

| Package | Standard Export Package(Detailed pictures as follows) | |||

| Country of Origin | CHINA | |||

Steel Sheet Piles

Steel sheet piles are long structural sections with a vertical interlocking system that create a continuous wall. The walls are often used to retain either soil or water. The ability of a sheet pile section to perform is dependent upon its geometry and the soils it is driven into. The pile transfers pressure from the high side of the wall to the soil in front of the wall.

Nucor Skyline supplies a wide variety of steel sheet piling. In piling, hot rolled steel sheet pile and cold-formed steel sheet

pile are two primary methods of manufacturing sheet piles. While there are differences between these two methods, the most important distinction is the interlock. Since hot-rolled steel sheet piling is produced from steel at high temperatures, the interlock tends to be tighter than its cold-formed steel sheet pile counterpart. Normally, looser interlocks are not recommended in extremely hard driving conditions or for walls requiring low permeability. Otherwise, the two types of sections perform similarly.

U shaped steel sheet pile has multiple advantages:

1.More durable interlocks: This allows the sheets to be driven and pulled many times before the interlocks are worn out

2.Better-suited for hard pile driving: The interlocks on hot-rolled sheet piles are also thicker and tighter than that of

cold-rolled sheet pile. This gives the sheet piles greater strength to be driven into tough ground conditions

3.Higher recycled steel content: LEED requirements sometimes dictate the use of recycled materials. Hot-rolled sheet piles have

almost 100% recycled steel content, while cold-formed sheet piles typically consist of around 80% recycled material

4.More water-tight: Hot-rolled sheet piles perform better in seepage tests, due in large part to the tighter interlocks

SPECIFICATIONS FOR :

The size of 400x100x10.5mm Type 2 Hot rolled U type steel sheet pile for construction.

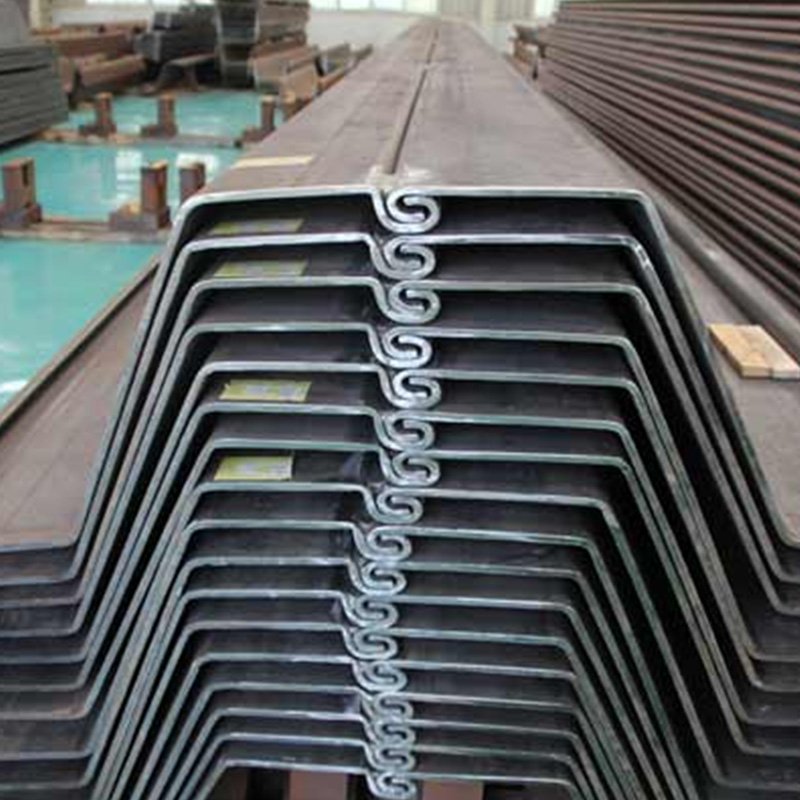

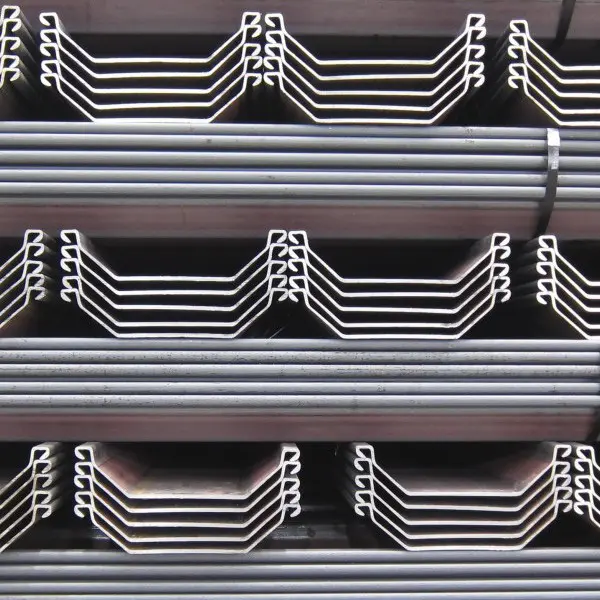

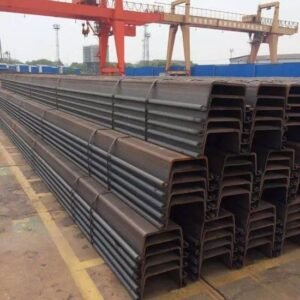

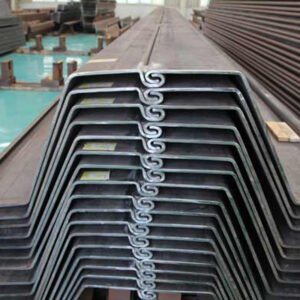

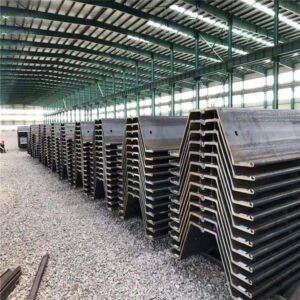

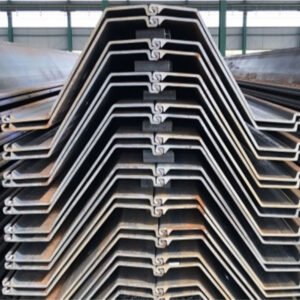

Picture show of Construction used U type steel sheet pile hot rolled 400x100x10.5mm price per ton.

JIS Standard Channels:

| Dimensions (mm) | Unit Weight (kg/m) | Dimensions (mm) | Unit Weight (kg/m) |

| 50X25X(3.0-5.0)X6.0 | 2.37-3.46 | 125X65X5.5X8.0 | 12.91 |

| 75X40X3.8X7.0 | 5.30 | 125X65X6.0X8.0 | 13.40 |

| 75X40X4.0X7.0 | 5.60 | 150X75X5.5X7.3 | 14.66 |

| 75X40X4.5X7.0 | 5.85 | 150X75X5.7X10.0 | 16.71 |

| 75X40X5.0X7.0 | 6.92 | 150X75X6.0X10.0 | 17.90 |

| 100X50X3.8X6.0 | 7.30 | 150X75X6.5X10.0 | 18.60 |

| 100X50X4.2X6.0 | 8.03 | 150X75X9X12.50 | 24.0 |

| 100X50X4.5X7.5 | 8.97 | 200X80X7.5X11.0 | 24.6 |

| 100X50X5.0X7.5 | 9.36 | 200X90X8.0X13.5 | 30.3 |

| 125X65X5.2X6.8 | 11.66 | 250X90X9.0X13.0 | 34.6 |

| 125X65X5.3X6.8 | 12.17 | 300X90X9.0X13.0 | 38.1 |

GB Standard Channels:

| Size | Specification(mm) | Theory Weight (kg/m) |

||

| h | b | d | ||

| 5# | 50 | 37 | 4.5 | 5.438 |

| 6.3# | 63 | 40 | 4.8 | 6.634 |

| 8# | 80 | 43 | 5 | 8.045 |

| 10# | 100 | 48 | 5.3 | 10.007 |

| 12# | 120 | 53 | 5.5 | 12.059 |

| 12.6 | 126 | 53 | 5.5 | 12.319 |

| 14#a | 140 | 58 | 6 | 14.535 |

| 14#b | 140 | 60 | 8 | 16.733 |

| 16#a | 160 | 63 | 6.5 | 17.24 |

| 16#b | 160 | 65 | 8.5 | 19.752 |

| 18#a | 180 | 68 | 7 | 20.174 |

| 18#b | 180 | 70 | 9 | 23 |

| 20#a | 200 | 73 | 7 | 22.637 |

| 20#b | 200 | 75 | 9 | 25.777 |

| 22#a | 220 | 77 | 7 | 24.999 |

| 22#b | 220 | 79 | 9 | 28.453 |

| 25#a | 250 | 78 | 7 | 27.41 |

| 25#b | 250 | 80 | 9 | 31.335 |

| 28#a | 280 | 82 | 7.5 | 31.427 |

| 28#b | 280 | 84 | 9.5 | 35.832 |

| 30#a | 300 | 85 | 7.5 | 34.463 |

| 30#b | 300 | 87 | 9.5 | 39.173 |

| 32#a | 320 | 88 | 8 | 38.083 |

| 32#b | 320 | 90 | 10 | 43.107 |

| 36#a | 360 | 96 | 9 | 47.814 |

| 36#b | 360 | 98 | 11 | 53.466 |

| 40#a | 400 | 100 | 10 | 58.928 |

| 40#b | 400 | 102 | 12.5 | 65.208 |

EN Standard Channels:

| Size | Dimensions (mm) | Unit Weight (kg/m) |

| UPN50 | 50X25X5X6.0 | 3.86 |

| UPN80 | 80X45X6X8.0 | 8.65 |

| UPN100 | 100X50X6X8.5 | 10.6 |

| UPN120 | 120X55X7X9.0 | 13.4 |

| UPN140 | 140X60X7X10.0 | 16.0 |

| UPN160 | 160X65X7.5X10.5 | 18.8 |

| UPN180 | 180X70X8X11.0 | 220 |

| UPN200 | 200X75X8.5X11.5 | 25.3 |

European Economical Channels:

| Size | Dimensions (mm) | Unit Weight (kg/m) | |

| UPE80 | 80X40X4.5X7.4 | 7.05 | |

| UPE100 | 100X46X4.5X7.6 | 8.59 | |

| UPE120 | 120X52X4.8X7.8 | 10.4 | |

| UPE140 | 140X58X4.9X8.1 | 12.3 | |

| UPE160 | 160X64X5.0X8.4 | 14.2 | |

| UPE180 | 180X70X5.1X8.7 | 16.3 | |

| UPE200 | 200X76X5.2X9.0 | 18.4 | |

Steel sheet pile is a type of steel with a lock, and its cross-section is straight, grooved and Z-shaped, and has various sizes and interlocking forms. The common ones are Larson, Lackawanna and so on. Its advantages are: high strength, easy to drive into the hard soil layer; can be constructed in deep water, if necessary, add inclined support to become a cage. Good waterproof performance; can form cofferdams of various shapes as required, and can be reused many times, so it is widely used.

Applications of Steel Sheet Piles

* Levee Strengthening

* Retaining Walls

* Breakwaters

* Bulkheads

* Environmental Barrier Walls

* Bridge Abutments

* Underground Parking Garages

Advantage

1.Abundant specifications and models.

2.The symmetrical structure is conducive to repeated use.

3.The length can be customized according to customer requirements, which brings convenience to construction and reduces cost.

4.Convenient production, short production design and production cycle.

5.Flexible design, a relatively high section modulus and mass ratio.

6.The stiffness of sheet pile wall is increased to reduce the displacement and deformation.

7.Large width, effectively save the time of hoisting and piling.

8.With the increase of section width, the water stop performance is improved.

9.More excellent corrosion resistance.

U-type steel sheet pile advantage:

1.Wide range of selections in terms of geometrical characteristics widening the choice of economically optimized profiles for particular project.

2.Great aptitude for repectitive use.

3.Wide range of section modulus, suitable for various type of contruction purpose.Service-proven to many type of projects,such as premanent structures temporary earth-retaining.

4.Works and tempoary cofferdams,etc.