Carbon Steel Bright Bar, Carbon Steel Round Bars, Carbon Steel Rods Suppliers and Dealer in China.

Carbon Steel Forged Bars Exporter, Carbon Steel Square Bar, Mild Steel Round Bar Specification, Carbon Steel Round Bar Specifications, Carbon Steel Round Bar, Suppliers of Carbon Steel Hex Bar, Carbon Steel Round Bars Manufacturer in China.

20CrMnTi(H) AISI 5120 Forged Round Bar ,SAE1045 C45 Hot Rolled Carbon Steel Round Bar Dia 50mm-200mm Cutting Steel Carbon Steel Rod Bar Carbon Steel Bright Bar rod ,

AISI 1045/1020/5140/4140/8620 ASTM A36/A572/A283 Carbon Steel Round Bar

Wisdom steel metal is a recognized manufacturer and exporter of CS Round Bars, which contain a small amount of incidental elements leftover from steelmaking. We also offer the same in different grades and specifications such as Carbon Steel Round Bars, Carbon Steel Round Bars, Carbon Steel Round Bars, Carbon Steel Round Bars, and EN SERIES Carbon Steel Round Bars.

To change the properties of Carbon Steel Square Bars is by adding alloying elements other than carbon that produce characteristics not achievable in plain carbon steel. Each of the approximately 20 elements used for Carbon Steel Flat Bars has a distinct influence on microstructure and on the temperature, holding time, and cooling rates at which microstructures change.

Wisdom steel metal is one of the pioneer stockiest and exporter for high-quality Carbon Steel Threaded Bars, which alter the transformation points between ferrite and austenite, modify solution and diffusion rates, and compete with other elements in forming intermetallic compounds such as carbides and nitrides. There is a huge amount of empirical information on how alloying in Carbon Steel Hollow Bars affects heat-treatment conditions, microstructures, and properties. In addition, there is a good theoretical understanding of principles, which, with the help of computers, enables engineers to predict the microstructures and properties of Carbon Steel Hexagonal Bars when alloying, hot-rolling, heat-treating, and cold-forming in any way.

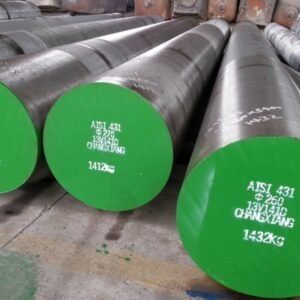

Product Specification and Size

| Hot Rolled Round Bar | Cold Drawn Square Bar |

| Hot Rolled Square Bar | Cold Drawn Hexagon Bar |

| Cold Drawn Round Bar | Forged Bar |

Available Size

| Product Name | Diameter (mm) |

| Hot Rolled Round Bar | 25~600 |

| Hot Rolled Square Bar | 21~54 |

| Cold Drawn Round Bar | 6~101.6 |

| Cold Drawn Square Bar | 6~50.8 |

| Cold Drawn Hexagon Bar | 9.5~65 |

| Forged Bar | 200~1000 |

Sae 4130 4140 4150 4340 Alloy Carbon Steel Round Bar

Carbon steel round bar Application industries :

Carbon steel bar is a kind of general-purpose steel bar that offers excellent formability and weldability, being used in a wide variety of applications including auto manufacturing, shipbuilding, aerospace industry, petrochemical plants, auto-power and wind-engine, metallurgical machinery, precision tools, etc.

– Auto manufacturing

– Aerospace industry

– Auto-power and wind-engine

– Metallurgical machinery

-Off-Shore Oil Drilling Companies

Power Generation

Petrochemicals

Gas Processing

Specialty Chemicals

Pharmaceuticals

Pharmaceutical Equipment

Chemical Equipment

Sea Water Equipment

Heat Exchangers

Condensers

Pulp and Paper Industry

-

4130: Good all-rounder, great for welded structures.

-

4140: The workhorse for high-strength, wear-resistant parts.

-

4150: For maximum hardness and wear resistance in the 41xx series.

-

4340: The premium choice for the most demanding applications requiring a combination of extreme strength and toughness.

These are all high-strength, hardenable alloy steels. Their properties are primarily determined by their carbon content and other alloying elements. They are typically supplied in the “annealed” or “normalized” condition and gain high strength and hardness through heat treatment (quenching and tempering).

Individual Steel Grades

1. SAE 4130 Steel

-

Properties: A popular chromium-molybdenum steel with medium carbon content. It offers a good balance of strength, toughness, and weldability. It is strong but less hardenable than higher-carbon grades.

-

Applications:

-

Aircraft engine mounts and structural tubing Automotive roll cages and chassis

-

Machine parts and jigs Pressure vessels

-

2. SAE 4140 Steel

-

Properties: A chromium-molybdenum steel with higher carbon than 4130. It is one of the most common alloy steels, known for its high strength, good fatigue resistance, and excellent wear resistance after heat treatment. It is tougher than 4150 but not as hard.

-

Applications:

-

Axles, shafts, and gears Bolts, nuts, and studs

-

Drill collars and tool holders High-strength machine components

-

3. SAE 4150 Steel

-

Properties: Similar to 4140 but with even higher carbon content. This results in superior hardenability, allowing it to achieve the highest hardness and wear resistance of the 41xx series. It is slightly less tough than 4140.

-

Applications:

-

Heavy-duty axles and drive shafts High-strength gears and sprockets

-

Military vehicle components Machine tools requiring extreme wear resistance

-

4. SAE 4340 Steel

-

Properties: A premium nickel-chromium-molybdenum steel. The addition of nickel gives it exceptional strength and toughness, even at very high strength levels. It has excellent deep hardenability, making it suitable for large, critical cross-sections.

-

Applications:

-

Aircraft landing gear and crankshafts High-strength bolts for critical applications

-

Heavy-duty gears, pinions, and sprockets Press rams and extrusion rams

-

Simple Comparison

-

Carbon Content & Hardenability: 4150 > 4140 > 4130. For 4340, its hardenability is superior to all 41xx grades due to Nickel.

-

Toughness (at similar strength): 4340 > 4130 > 4140 > 4150

-

Cost: 4340 (most expensive) > 4150 ≈ 4140 > 4130